The importance of construction practice in reinforced soil structures

The concept of adding a reinforcing element to a soil structure goes back thousands of years to Mesopotamia where one of the Ziggurats (ancient temples) in the desert of what is now Iraq is still standing, having been constructed with natural reed reinforcement. Parts of the Great Wall of China are also constructed with a similar concept. However, the use of geosynthetics in reinforced soil structures is somewhat more recent, dating back to the 1970’s.

As this technology has become more common throughout the world, they have become known by various names such as Mechanically Stabilised Earth, Geogrid Reinforced Soil and a few others. The concept has proven to be advantageous on so many sites and shown to save significant cost and provide better outcomes, that we are in danger of these wall systems becoming a victim of their own success.

So what does that mean?

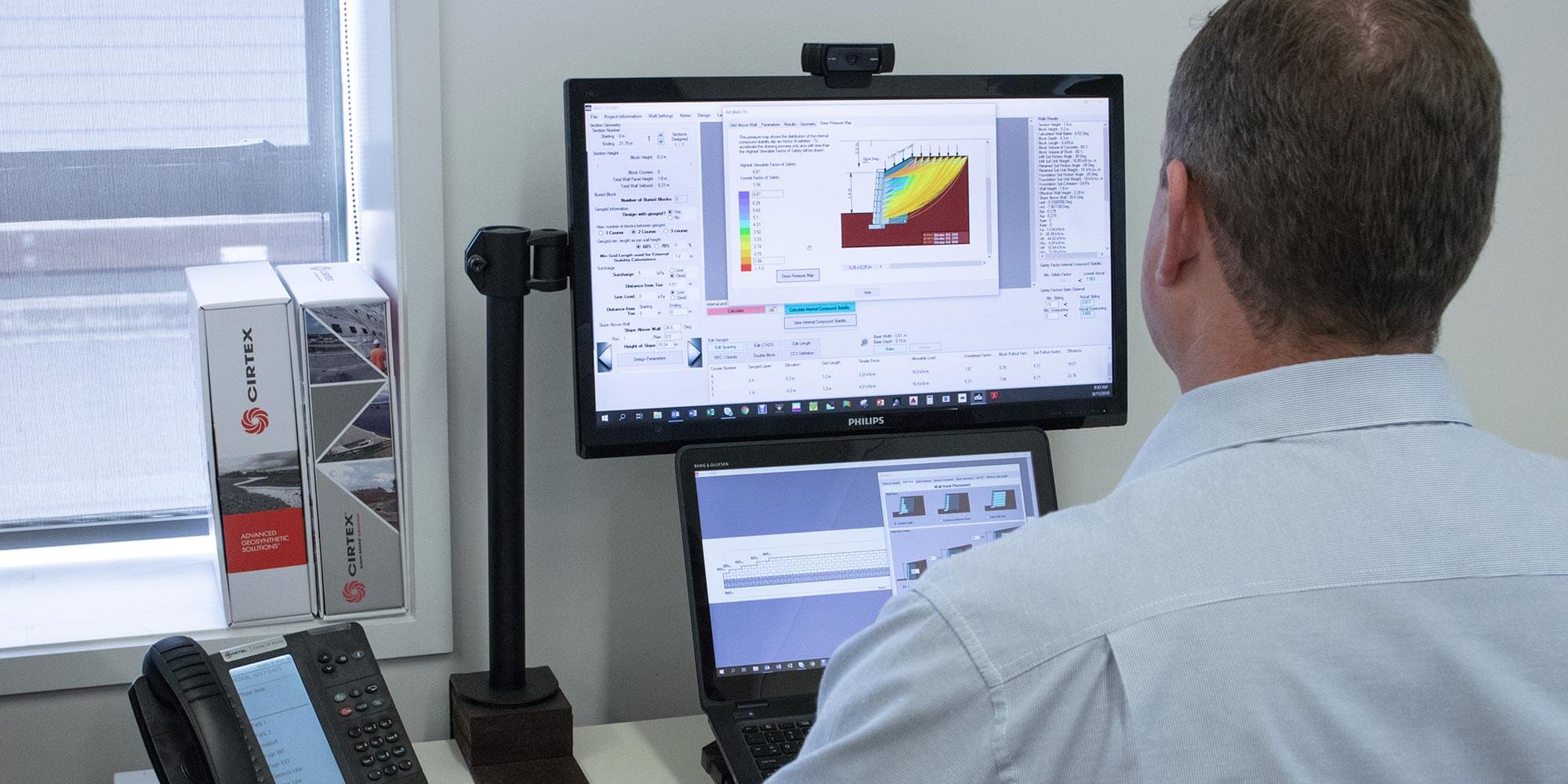

When using geosynthetics to stabilise a slope or build a retaining wall, the designer will take into account the most appropriate design method, which could be a geotechnical slope stability analysis or a wall design approach such as the tie back wedge or two part wedge analysis. There are a host of inputs and design considerations to consider, and thankfully we have some excellent software packages to make this easier. Although, good engineering judgement is still required.

Herein lies the issue

As the systems have been commercialised and become commonplace throughout the world, the danger is that we are starting to lose sight of the fact that they are still an engineered structure providing an engineered solution. To that end, they need to be built exactly as the engineer intended. A key to this is an understanding that these are predominately a soil structure, not a geogrid structure. If you look at the material content of the wall or slope, the soil or aggregate fill by content, or weight, is thousands of times more than the geogrid.

This means that things such as proper selection of the backfill, careful compaction, managing moisture content and providing drainage are critical to the success of the project. The danger is that any contractor with minimal training can move soil and lay grid down, but if they don’t understand the requirements of the system there will almost certainly be a post-construction issue.

We can do it right

The good news is that as an industry we can do it right. Well designed and constructed MSE walls and slopes have a very high success rate. A recent study into the cause of over 300 issues associated with failure or deformation in an MSE wall showed that not one of them was a geosynthetic failure. So, here’s a few things we can do right away to ensure the success of the project.

For the designer

As mentioned, there are many design packages which can be used, and most of them are excellent. However, it still behoves the designer to understand the concepts and be familiar with what the geosynthetic reinforcement is contributing to the overall stability. Any design printout will need to be carefully checked to ensure it integrates with the project site and considers all the necessary input factors. It is also very important for the designer to have input into the construction monitoring. This may not be easy, as it may be a different contract, but no designer wants to see their design fail, so bear this in mind during any contract negotiations. It’s also a great idea to reference a reputable construction best practice guide.

For the contractor

There is a lot of benefit to a contractor to win a reinforced soil project. However, we must realise that there is a high level of skill required. They will need to be familiar with the required design outcomes, understand the importance of the compaction levels, required fill types, drainage detailing and facing construction to name a few. A preconstruction meeting with the design engineer and a comprehensive best practice or construction methodology should be considered a minimum requirement.

For the client

The client is focussed on a successful outcome to the project and is usually very sensitive to the cost. For a client, I have one and only one thing to say. The cheapest way for you to get a successful outcome is to build it right the first time. Any rework or deconstruction required will cost you exponentially more. Look for a contractor with experience, or even better with a certification as an approved installer, and ensure they work collaboratively with the designer.

Summary

Geosynthetic reinforced walls and slopes have proven to be one of the most effective methods of grade change on infrastructure and land development projects. As with any material there are dangers associated with inexperienced practitioners, however, when properly managed these structures have a bright future for sustainable infrastructure.