BentoSure® GCL

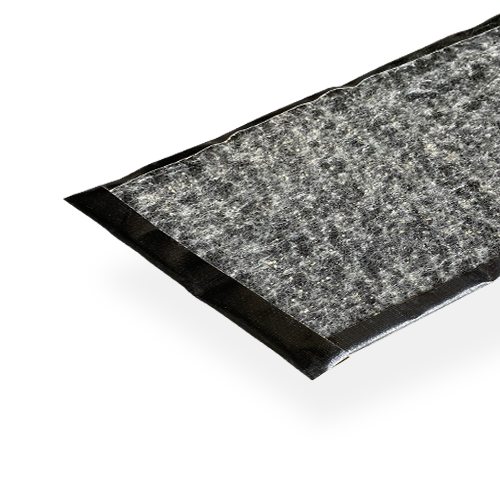

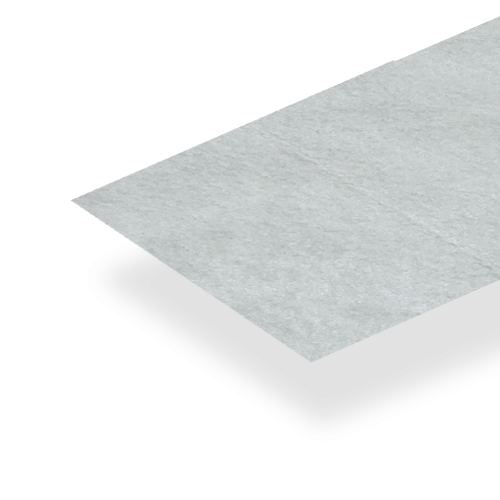

BentoSure® is a reinforced needle punched geosynthetic clay liner (GCL) which is made by encapsulating a layer of high quality sodium bentonite between two geotextiles.

BentoSure GCL is a needle punched, reinforced barrier system that combines two durable geotextile outer layers and a core of high swelling sodium bentonite clay. This forms a uniform, multidirectional, shear resistant hydraulic barrier with self-sealing characteristics. BentoSure can also be supplied with a polymeric membrane attached for additional performance benefits.

Manufactured from strong and durable geotextiles in combination with fine granular sodium bentonite, ensuring the long term performance of the liner. When hydrated, the bentonite swells to form a low permeability layer with the equivalent hydraulic protection of a thick compacted clay layer.

BentoSure is commonly used for water reservoirs, dams and river embankments, liquid wastes disposals sites, transfer stations, secondary containment, solid wastes storage and disposal sites where the high performance, guaranteed quality, and ease of installation make it an economical and environmentally responsible option.

BentoSure NW5000C has an additional 200gsm polymer coating on one side of the GCL. This provides extra protection and assurance for critical designs such as high water head applications, contaminated soils and installations prone to desiccation.

Downloads

- Technical Information

- Installation

Frequently Asked Questions

A minimum of 300 mm of cover should be maintained between the equipment tires/tracks and the GCL at all times during the covering process. The weight of this soil is also relied on by the BentoSure to allow it to function as designed.

It is typically recommended to use a suitably designed Spreader Bar to unroll BentoSure onsite. It should be considered that roll weights can be from 700 to 1500kgs so proper strength of the materials used has to be ensured. These can be hired from Cirtex, contact us to find out more.

Benefits & Features

- Reduced transport costs and emissions

- Robust geotextile encapsulates and contains the bentonite

- Handles differential settlement better than compacted clay liners

- High shear strength and interface friction

Specifications

Code

Product

Size