Enatel Development, Christchurch – Triton Stormwater System

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

Based in Christchurch, Enatel are a world leading designer and manufacturer of advanced charging solutions. As part of their expansion, they are building a warehouse within Christchurch International Airport’s new freight and logistics development, Dakota Park. With no stormwater systems in place, three rock-filled soakage pits were originally proposed to be placed under car park areas, but the consultant also approached Cirtex to provide a Triton Stormwater System design. Triton provided the client with a maintainable system and a significantly extended design life over the rock-filled option.

DESIGN

Catering for a one-in-fifty year storm event, three single-layer Triton stormwater systems were designed to fit in with the drainage design for the site. While the Header Row in a standard Triton System would normally be placed along one edge ofthe design, the flexibility of the Triton configuration allowed the main Header Row to run through the centre of the system,with overflow pipes placed on either side to flow into chambers. Two 450mm inlet pipes were installed at either end of the system, requiring 5 outlet pipes on either side to cater for larger storm events. Designated catchments to the north, west and east of the site captured a combination of roof and yard stormwater runoff, discharging into the Triton systems which had a soakage rate of 167mm/hr. The three systems had a combined 553m3 soakage volume, collecting water from a 15,585m2 area.

INSTALLATION

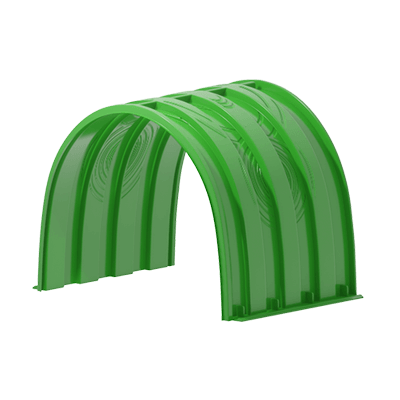

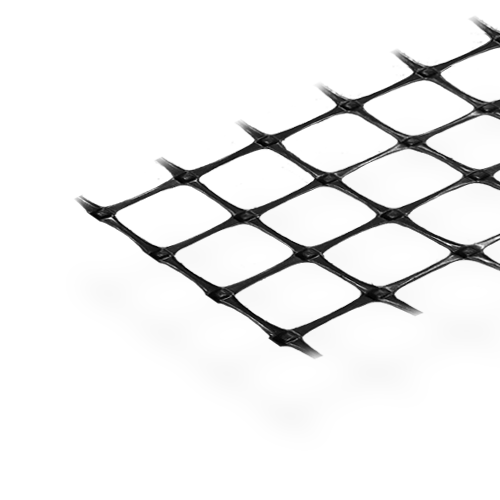

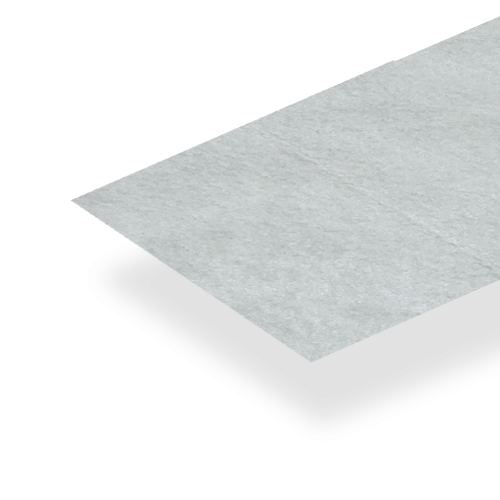

To fit in with the construction programme, the North Pit was installed first. The Triton system sits on a layer of DuraGrid X 20/20 covered by a 150mm layer of aggregate. Triton chambers are light and easy to handle manually, simply clipping in place, making for fast installation, especially once the initial row is accurately placed. The Triton chambers were then covered with washed drainage aggregate to 150mm above the top chamber, before being wrapped with DuraForce AS410 geotextile. A minimum of 450mm engineered fill was placed on top, compacted in 150mm lifts, before the surface pavement was placed.

Before installation of the East pit began, a redesign of the Triton system was required to cater for site constraints and services installed around the pit. Cirtex were able to quickly recalculate a revised system size for the volume required, changing from a 25m x 8m pit that was five chambers wide, to a longer design that was only three chambers wide. Thanks to Triton’s versatility,

a new configuration was quickly designed, allowing contractors to reconfigure their excavation and installation without delaying the site programme.

With a new warehouse built close to the airport in Dakota Park, Enatel are looking forward to expanding their business, and thanks to Triton, they have future proofed their stormwater requirements.

The products used provided the following benefits to the project:

- Lightweight, easy to handle and quick to place.

- Versatile design for multiple configurations

- Cost-effective, eco-friendly stormwater solution

- Unmatched strength and durability