Black Jack Road Slip Repair – DuraMesh® MSE Wall

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

On the Coromandel Peninsula’s winding Black Jack Road leading to Opito Bay, heavy winter rainfall combined with a wet summer caused repetitive slips halfway between Kūaotunu and Otama Beach. An 80m section of the road slumped approximately 1m, reducing the road to one lane, making access difficult for tourists and residents.

Thames Coromandel District Council desired to rebuild the shoulder. Looking for an easy to construct solution that could be vegetated to blend in with the natural surroundings, HD Geo and Pinnacles Civil turned to DuraMesh Panels lined with BioWool.

DESIGN

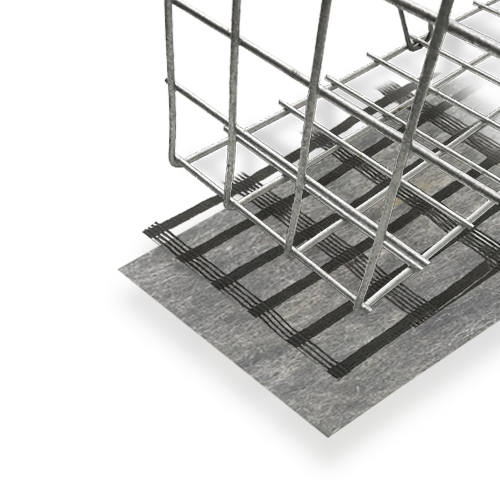

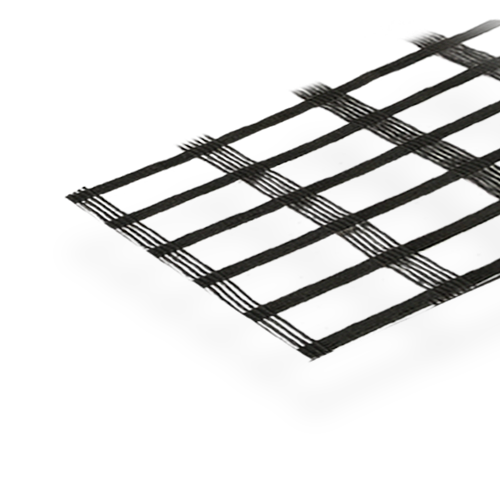

Following the elevation of the road, this 94m long, 2m high, curved DuraMesh MSE wall with StrataGrid tieback was designed by HD Geo with a 70° angle to imitate the natural slope of the surrounding landscape. 2.5m strips of StrataGrid would be placed within compacted layers of engineered fill at each lift. A layer of Armourflow Panel Drain would be placed against the cut face to remove the need for drainage aggregate. This would help prevent excavating too far into the road, allowing Kelsey Construction to keep one lane operating for local traffic whilst building the wall.

BioWool would be wrapped inside each panel, which would then be hydroseeded to allow vegetation to grow.

INSTALLATION

Work began by clearing slip material and vegetation from the site. The cut face was excavated to shape the bank to fit the design 2.5m from where the DuraMesh wall would be placed. DuraMesh cages and StrataGrid were delivered when required from Thames so as not to clutter up the tight site. The first layer of GAP65 backfill was compacted and tested to 95% Maximum Dry Density, with each subsequent layer compacted and tested in 150mm lifts before another layer was placed. A 110mm subsoil drainage pipe was placed against the bottom of the cut face to disperse water collected within the Armourflow.

DuraMesh cages can easily be cut and placed to fit the curvature of the design. Once the cages were hogtied together, the BioWool layer was pressed into the cages before StrataGrid was placed, with the two sizes of bracing hooks pressed through the BioWool to lock the 70° angle in place.

Reducing traffic to one lane, the eastbound lane was stripped back to sound pavement, with the surface releveled and resurfaced with a new kerb and channel once the DuraMesh wall was complete.

With the DuraMesh wall hydroseeded, natural vegetation will slowly take over, allowing the wall to blend in with the surrounding environment. Like the rest of the Coromandel ranges, it will become a lush green, supportive bank that can withstand any overly wet seasons to come.

The DuraMesh system provided the following benefits to the project:

- Can be cut and shaped to create curves or sharp angles

- Can be vegetated using BioWool

- Are light and easy to handle