Coastal View Retirement Village – MagnumStone™ Gravity System

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

As part of their new, architecturally designed Coastal View Retirement Village on the Tāhunanui Hills in Nelson, Qestral Corporation Ltd sought a retaining wall solution that would optimise the space available, whilst adding to the aesthetics of their new generation retirement village. With construction to commence at the start of winter, Schick Civil Construction and Aurecon approached Cirtex regarding the construction of three MagnumStone retaining walls.

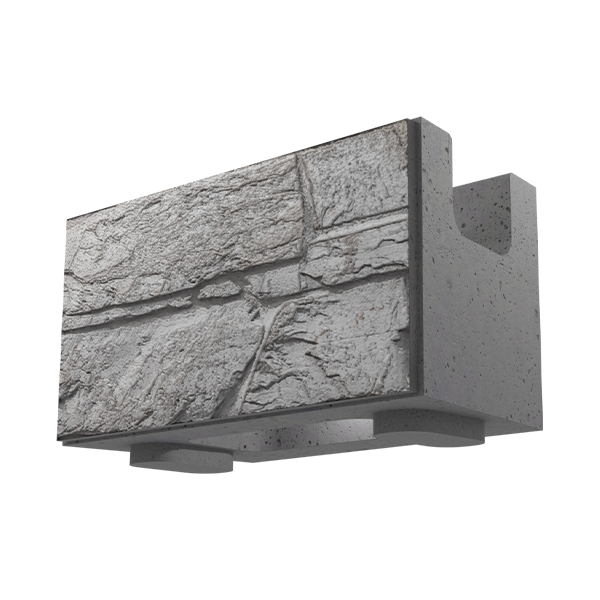

With the possibility of different design methods required, MagnumStone gravity walls provided the ideal solution in areas of the site where a low height, in-cut retaining wall was required. With high quality, locally sourced fill available, the MagnumStone gravity system could easily transition to the more cost effective Mechanically Stabilised Earth (MSE) solution for the higher walls where more fill was necessary. Each wall had unique design requirements, yet all walls required their finished aesthetics to be consistent throughout the site.

DESIGN

Two MagnumStone gravity walls with extenders were designed. Approximately 60 m and 80 m in length, their design height varied from 0.9 m to 2.1 m. The gravity wall system allowed for shorter tieback length compared to the height of the wall. The preliminary layout included several corners with tight curves, which MagnumStone blocks can produce, however Aurecon concluded that squared-off corners would best optimise the space available and add to the overall aesthetics of the village.

Guided by Cirtex, Aurecon created some well-thought-out designs, detailing the exact layout of how MagnumStone blocks and extenders would fit together in relation to those corners. This important step in the design phase ensured accurate quantities, meaning the right materials turned up on-site.

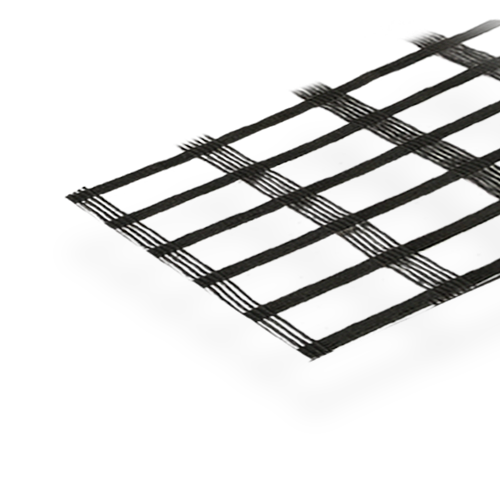

A third wall, at 186 m long with a design height ranging between 0.5 m and 3.7 m high, also included a 3.3 m wide, 37 m long ramp connecting the upper and lower levels. A gravity wall was initially considered. However, due to the height of the wall, the MagnumStone MSE design option with a 3m StrataGrid® tieback proved more cost effective.

The ramp was designed as a tiered wall system, requiring additional checks to assess not only the individual walls, but to ascertain what effect the upper wall had on the lower wall, ensuring this was accounted for in the overall design.

INSTALLATION

Due to a wet winter, Schick Civil Construction were challenged with extreme rain and saturated site material. Unable to add backfill as they laid each layer of MagnumStone, Schick were able to keep the project progressing by stacking MagnumStone up to four blocks high with the StrataGrid wrapped in place without backfilling, giving them time to dry out material on the wet site.

This was Schick Civil Construction’s first time using MagnumStone. Setting themselves a target of 70m2 per day on the larger wall, they soon became familiar with MagnumStone’s ease of installation. The two smaller walls then took only two days each to install, including base prep, two to three layers of blocks, infill and backfill.

The flexibility of the MagnumStone system meant that the design and construction method could easily change from a gravity wall to MSE wall without disrupting the overall aesthetic. The walls were completed using 150mm capping blocks, creating a tidy, continuous top edge along the entire structure. Placement of the caps was made easy by using Cirtex’s custom designed gravity clamp attached to a small excavator, which flips, lifts and places each cap onto the blocks.

The Sleeve-It® Post Anchoring system was used to facilitate installation of fencing above the wall. Although MagnumStone blocks incorporate a void where fencing posts can be installed without interfering with the grid, Sleeve-It also allows for offsetting the fence back from the edge without compromising the StrataGrid beneath.

Desiring an aesthetically pleasing retaining wall system that could be built during winter in challenging conditions, Qestral Corporation Ltd were successfully able to maximise land use and keep construction going by using the MagnumStone system.

The MagnumStone system used provided the following benefits to the project:

- Aesthetically pleasing and consistent facing

- Ability to adopt different construction methods depending on design requirements

- Flexibility of installation methods meant construction could continue in overly wet conditions