A key challenge in getting geosynthetics more widely accepted in the industry is to use them not only on keynote projects, but smaller, everyday projects. To do this, we must help design engineers quantify the benefits of the geosynthetic and this is especially applicable in the stabilisation application.

In the geosynthetics industry, all major suppliers provide a significant amount of research and testing data. Academics and universities also do field and laboratory testing. The challenge is applying that data in a practical, repeatable way on a construction site.

What are the barriers to geosynthetic stabilisation in a foundation application?

- The overuse of ‘rule of thumb’ processes. Although many of these generalisations are accurately based on specific test data, they are not precise enough for a design engineer to use when signing off on a project.

- A lack of understanding of the actual engineering functions. Knowing a process works but not understanding why, often prevents development and progress. We want to quantify and explain the specific engineering functions at play.

- Applying field and lab tests in real life situations. Full scale laboratory or large-scale field tests in a foundation application have a large number of variables. These include the subgrade material, the moisture content of this material, the geosynthetic type and grade, the type, thickness, and angularity of the basecourse aggregate used. Is there separation provided by a geotextile and finally what compaction was achieved? Each variable affects the outcome, and if we can’t replicate them exactly on your specific project site, then the results from those tests are a challenge to apply.

- The speed and accuracy of available test methods may not be appreciated by the market because they have developed so much in recent years.

We’re examining shallow foundations, not road pavements

Road pavement applications for a geosynthetic are generally designed to extend the life of the pavement by reducing rutting. We already have quantifiable data for that, but not so much for shallow foundation applications, such as a raft foundation.

The engineering functions we’re testing are reinforcement, stabilisation, or a combination of both. Reinforcement introduces a tensile element into an aggregate layer. Stabilisation seeks to stiffen or stabilise the aggregate combination.

The engineering functions we’re testing are reinforcement, stabilisation, or a combination of both. Reinforcement introduces a tensile element into an aggregate layer. Stabilisation seeks to stiffen or stabilise the aggregate combination.

Following is a brief overview of two situations where we used the Plate Load Test (PLT) and the Lightweight Deflectometer (LWD) test to measure modulus. Both tests can be correlated back to an assumed CBR. Both are suitable for coarser aggregates and give a measure of stiffness in Megapascals. The PLT gives a direct modulus readout, but more importantly, loads the subgrade significantly deeper than a lot of other common tests.

Application 1 – The Project Challenge

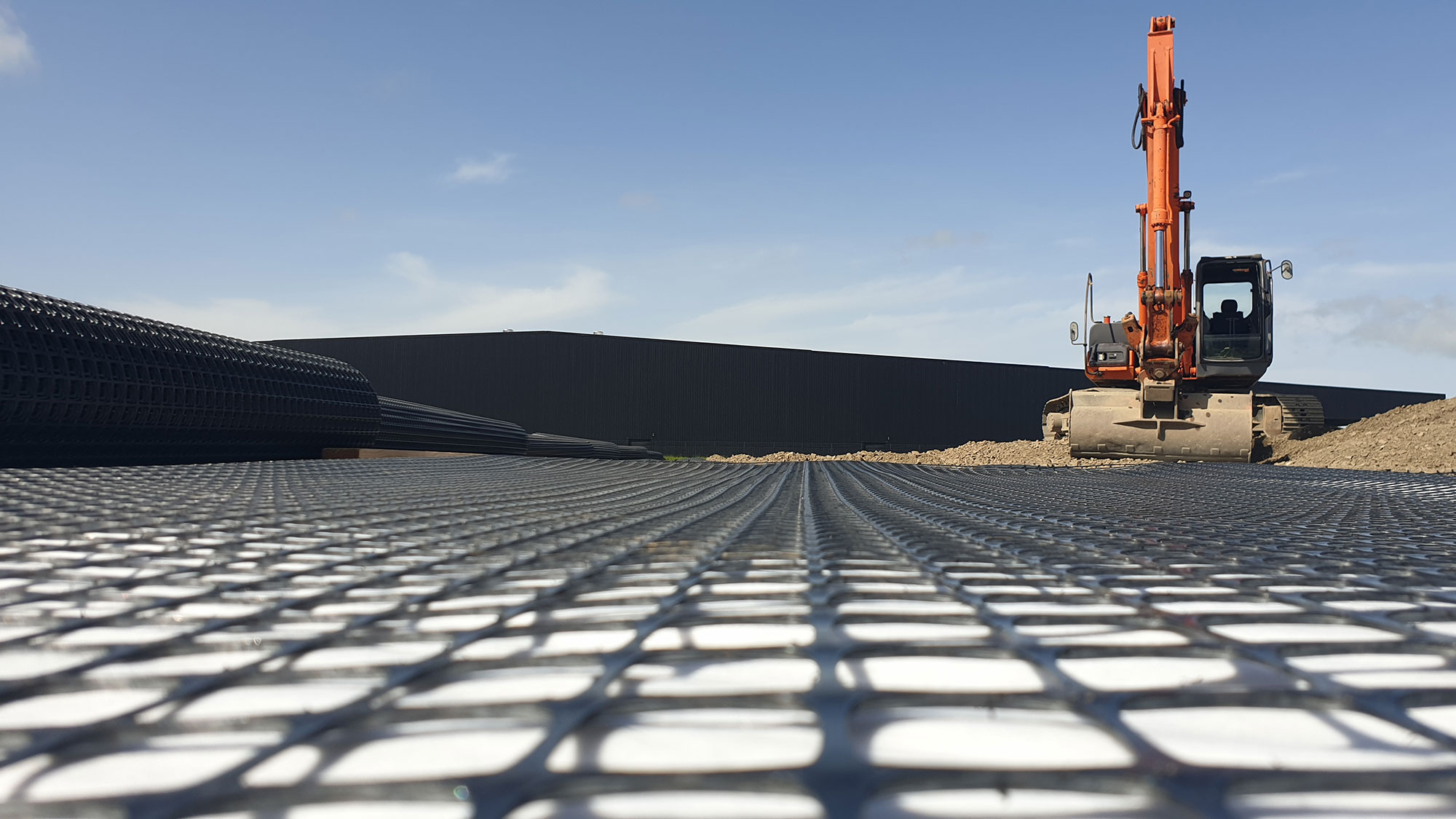

A 30,000 sqm warehouse on a site with 600 mm to 900 mm of loose silt, known locally as loam, layered over a dense sand. The sand gave a very good foundation, but there were questions about the loose silt being very soft and compressible.

The initial design was to remove and replace the entire loam layer. This required a lot of cartage and quarried aggregate being brought into the site. The contractor approached Cirtex about placing a 300 mm layer of imported aggregate on a stiff, polypropylene geogrid. We proposed the DuraGrid X 30/30 over a separation geotextile, DuraForce AS280. This would save 13,500 m3 of quarried aggregate, along with 27,000 m3 of cartage.

But the question remained. Would it give the required support to the industrial floor foundation?

Working closely with the design engineer to identify what output they needed, we set up a trial section on site. We used PLT and LWD tests on the dense-sand lower foundation, the silty loam layer, and the raft trial section. From those results, the design engineer was able to give the floor slab designers accurate modulus of subgrade reaction and stiffness on each layer.

We saved the 13,500 m3 of quarried resource, and the 27,000 m3 of cartage to and from the site, and although saving money on a site with geosynthetics is not a new concept, a key benefit was being able to quantify it on a smaller, commercial development, the kind of thing that’s happening all day, every day, right through the country.

Application 2 – The Commonly Required Situation

There is a marked increase for requiring shallow aggregate raft foundations in residential and commercial applications right throughout the country, primarily used to mitigate seismic effects, in particular liquefaction. With limited Government advice on what to use, one typical solution suggests an expensive M/4 AP40 aggregate, which is seldomly used in residential or commercial applications. As an alternative, people use GAP65 or other locally sourced material, but this can significantly change the performance of the raft and the interaction with the geogrid, which in effect means the typical solution is being followed.

The challenge coming from the market was to discover the benefit gained in that application by putting in a geogrid, and which of the commonly used geogrids worked best? For our tests we used GAP65, as it was the most requested aggregate.

We set up a test bed on a green field site, excavated down to a very soft subgrade. This was to simulate a loss of support, as opposed to a seismic event. To minimise potential variations in the subgrade, the control section and three commonly used grids were set up next to each other in 2 m by 2 m test sections. The modulus was tested at 200 mm of thickness with one layer of geogrid, then at 400 mm of thickness with two layers of geogrid, then with another 200 mm of aggregate, so 600 mm with two layers of geogrid. A consulting laboratory from WSP did the actual testing.

From this, we were able to quantify the benefit of using a geogrid in this application between a control section and a 400 mm and 600 mm raft foundation. We could compare commonly used grids and were able to help engineers and contractors clarify what could be used.

In summary

The benefit of a geogrid in a pavement or a foundation application will be reinforcement, stabilisation, or a combination of both. These benefits are engineering functions that can be measured and compared, in some cases more simply and cheaply than we think.