Subsoil drainage systems are critical components of infrastructure, designed to manage subsurface water effectively and ensure the long-term stability of structures. Achieving long-term steady-state flow in these systems is essential for their functionality and durability. This paper explores the principles of subsoil drainage, the importance of proper filtration, and the methods used to design systems that can last for decades without clogging or failure. A key purpose was to determine the most suitable pipe filter with a commonly used backfill material that would reflect what is typically constructed in the field, rather than assuming an expensive and rarely available graded material. In particular, we consider the performance of Filter Sleeve as a pipe sleeve filter in comparison to a geotextile wrapped trench or a geotextile wrapped pipe.

Surface vs Subsurface Drainage: Why Separation is Critical in Civil and Infrastructure Design

A fundamental distinction in drainage engineering is the difference between surface drainage and subsurface drainage. This may seem obvious but is often overlooked. Surface drainage is designed to manage water flowing over the ground, such as rainwater runoff, while subsurface drainage deals with water within the soil. These two systems serve distinct purposes and must remain separate to function effectively.

Surface water typically has higher flow volumes, faster velocities, and carries suspended sediments. Due to the hydrodynamics of sediment transport, these sediments are typically all similar in size for a given flow event, which means they are likely to be a completely different grading to the subsoil conditions. If surface water is directed into a subsoil drainage system, it can blind off the system, whether it be a graded aggregate system or a filtration fabric system. Subsoil drainage systems are specifically designed for the slow, steady flow of water through soil, and introducing surface water disrupts this balance. Therefore, proper separation of surface and subsurface drainage is a critical design consideration.

- Surface and subsurface drainage serve distinct hydrological functions and must be kept separate.

- Surface runoff carries sediments that can clog subsoil systems if not properly managed.

- Subsoil systems are designed for slow, consistent flows and are easily compromised by high-velocity surface water.

- Separation of these systems ensures optimal performance and prevents long-term failure.

Designing Long-Life Subsoil Drainage: Soil Filtration Principles for 100-Year Performance

Most filtration systems, such as air and water filters, require regular cleaning or replacement to maintain functionality. However, subsoil drainage systems are expected to function for decades, often up to 100 years, without maintenance. This longevity is achieved by leveraging the natural ability of soil to transport water within its structure.

In undisturbed soil, water flows naturally through the soil matrix. Subsoil drainage systems replicate this natural process by creating a soil filter that allows water to flow from the soil in its natural state, through the soil filter that is created around the subsoil system, and into the drainage system. This soil filter is the key to achieving long-term steady-state flow.

In this blog, we are discussing the scenario of water flowing in one direction into a drainage system, as opposed to dynamic flow where water can reverse direction, such as tidal areas. This is covered in the referenced literature at the end of this blog but is not the subject of this discussion.

- Subsoil drainage longevity depends on mimicking natural flow through soil using engineered filtration.

- Soil filters provide a maintenance-free solution by gradually transitioning flow into the drainage system.

- Key to success is maintaining one-directional flow and avoiding systems subject to tidal or dynamic reversal.

- Properly designed systems can function effectively for up to 100 years without replacement.

Subsoil Drainage Design: Soil Permeability, Filter Compatibility, and Long-Term Flow Performance

The effectiveness of a subsoil drainage system depends on the flow of water through the soil and into the drainage conveyance pipe or trench. This flow can be governed by either the in-situ soil’s permeability or the soil filter surrounding the drainage system. In some cases, the capacity of the drainage pipe itself may govern, but this is less common. Therefore, designing a subsoil drainage system requires careful consideration of the soil’s ability to transmit water and the compatibility of the subsoil filter system used.

Unlike particle filters, which require cleaning or replacement, soil filters can achieve long-term steady-state flow. This is accomplished by using granular aggregates or geotextile filters to support the soil structure. The purpose of the filter is not to block fine particles but to provide structural support to the soil, allowing water to flow freely. This gradual transition from the natural soil to the soil filter ensures steady-state flow over many years.

- Design must account for both in-situ soil permeability and the characteristics of the filter material.

- Granular or geotextile filters support soil structure without blocking fine particles, enabling steady-state flow.

- Most subsoil systems are filter-limited, not pipe-limited, in terms of capacity.

- Smooth hydraulic transition from native soil to filter is essential for system longevity.

Testing Soil Filter Performance: Gradient Ratio Method and Geotextile Validation for Subsurface Drainage

The design of soil filters is guided by well-established principles found in geotechnical engineering literature. These principles are based on the particle size distribution of the in-situ soil and the aggregate used in the filter, or the pore size of the geotextile. By matching these properties, engineers can create a filter that supports the soil structure while allowing water to flow.

Establishing the long-term performance of the filter system (as opposed to just the pipe or the filter alone) includes designing for various cases. The FHWA Design guide is a comprehensive example of this, considering retention of soil particles, prevention of clogging and blinding, permeability and durability.

The method proposed by Luettich, et al. and published in many places including “Designing with Geosynthetics” by Dr RM Koerner is similarly comprehensive.

In addition to the analytical methods described, a laboratory method for evaluating soil filter performance is the gradient ratio test. This test is codified as ASTM D 5101 and measures the flow of water through a combination of soil and filter fabric under controlled conditions. This test produces a result that is specific to the fabric used and the tested soil. It provides the designer with a ratio between the hydraulic gradient of the soil sample, and the hydraulic gradient of the soil-fabric interface, or more specifically the soil filter created. In addition, it gives a hydraulic conductivity of the filtration system.

However, drainage systems are installed every day in thousands of projects worldwide, and it is not common practice to produce a drainage design, or feasible to conduct a specific test, for each one. To this end, Cirtex commissioned TRI to conduct tests with three common geotextile types, using a generic silty sand material as commonly found at landscape supply and aggregate yards, and readily available and often a site won material throughout New Zealand and Australia

The purpose of this testing was to establish the long-term performance of various filter systems when combined with a silty sand backfill, which is readily available and cost effective. This allows designers to confidently select common components which are readily available with predictable performance.

- Gradient ratio testing (ASTM D 5101) provides measurable performance data for soil-filter interactions.

- Matching filter properties to soil particle size distribution is key to preventing clogging and piping.

- Cirtex testing with generic silty sand offers practical data for real-world conditions in NZ and Australia.

- Proven geotextiles give engineers confidence in specifying common, locally available materials.

Geotextile Types for Drainage: Performance Characteristics and Suitability for Soil Filtration

There are four main types of geotextiles used in drainage. An understanding of these helps us to design better filtration systems.

Tubular Knitted Fabrics are made in a continuous length on a rotary knitting machine, using a unique lock stitch. They are characterised by having a 3-dimensional textile and larger pore size than other textiles

Thermally Bonded geotextiles are produced by laying polymer fibres on a bed – a process called spun bonding – then binding them together by passing through heated rollers. Thermally bonded fabrics are often used for prefabricated drains.

Needle punched geotextile is also produced on a spun bonding process, then needled together rather than heat bonded. This type of fabric is most commonly used for drainage applications.

Slit film Woven fabrics are not recommended for drainage applications as the structure of the fabric does not allow for the efficient formation of the soil filter.

- Tubular Knitted: 3D structure with large pore size; ideal for high-flow applications like pipe sleeving.

- Needle Punched: Most common for drainage; durable and widely used in trench systems.

- Thermally Bonded: Suitable for prefabricated drains; made with spun bonding and heat setting.

- Slit Film Woven: Not suitable for drainage; structure inhibits soil filter formation and flow.

Wrapped Drains vs Fabric Covered Pipes: Surface Area, Flow Capacity, and Design Considerations

Fabric Wrapped Drains, sometimes called French drains, comprise a trench lined in a geotextile fabric and filled with a drainage aggregate. Sometimes, an additional pipe is laid in the trench for conveyance, and sometimes the drainage aggregate itself is used for conveyance. A wrapped drain has a large surface area of filter fabric and therefore soil filter, generally up to 3m2 of filter area for each metre of drain for a 1m deep by 0.5m wide trench.

Fabric Covered pipes, either round or some proprietary shape, are drain systems which are characterised by having the filter fabric directly around the pipe rather than around the outside of the trench. This option can be a lot more cost effective to install but clearly has a much-reduced surface area, so needs specific design consideration. In a common application with a 110mm pipe, the filter system area is often about 10% of the area of a wrapped trench. A specifically designed pipe filter such as Filter Sleeve with a high long-term flow can offer a more economical option without compromising performance in many applications.

- Fabric wrapped drains offer high filter surface area, making them ideal for trench installations.

- Fabric covered pipes are more cost-effective but have reduced surface area and need specific design.

- Filter Sleeve enhances flow rates in low-surface-area applications like pipe sleeving.

- Design must balance cost, performance, and available space to choose the right system.

Laboratory Study of Filter Sleeve vs Needle punched and thermal bonded geotextiles

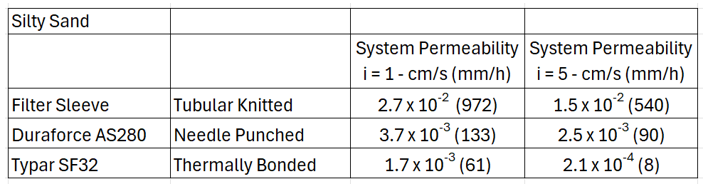

In consideration of the need for a reliable and commercially feasible solution to the challenges faced above, Cirtex commissioned TRI to perform gradient ratio testing on various fabric combinations with a silty sand, to replicate a non-engineered but readily available backfill material. The system permeability after steady state has been achieved gives a representation of how the filter system will perform.

Hydraulic gradients from 1 to 10 are presented in the report, with i = 1 and 5 represented here. As a subsoil system is expected to draw down water to approximately the pipe grade, this range of gradients seems the most realistic.

As we can see from the published system permeability, the larger pore sizes of the Filter Sleeve, combined with the soil filter formed around it, provided significantly more flow while still preventing piping and loss of fines.

- Gradient ratio testing shows Filter Sleeve allows significantly higher flow in silty sand backfill.

- Tests at hydraulic gradients i = 1 and 5 represent realistic field conditions.

- Filter Sleeve’s large pore size supports high system permeability while preventing soil loss.

- Results provide practical performance data to guide material selection for common backfills.

Optimising Subsoil Drainage Performance: Filter Sleeve vs Geotextile Wraps for Long-Term Flow Capacity

Achieving long-term, steady-state flow in subsoil drainage systems is a complex but essential task in geotechnical engineering. By understanding the principles of soil filtration and designing systems that replicate the natural flow of water through soil, engineers can create drainage systems that last for decades without maintenance. The use of granular aggregates, geotextile filters, and advanced testing methods such as the gradient ratio test ensures that these systems function effectively and reliably.

When using a readily available backfill material which does not have a specific engineered grading, Filter Sleeve can demonstrate significantly higher long-term steady-state flow as compared with other geotextile types. This makes it more suitable for pipe sleeving situations where the surface area of the filter system is much less than a wrapped trench scenario.

In all tests conducted, there was no soil migration through the geosynthetic, demonstrating that the flow conditions did not result in piping of the in-situ soils

For a 110mm diameter punched pipe with Filter Sleeve laid in a silty sand bedding material, the drainage system can be expected to allow the free passage of ≈ 5.6 litres of water per minute per metre of length, as opposed to 0.35 litres for a spun bonded fabric on the same pipe.

While non-woven fabric is a suitable filter medium to utilise in a fabric wrapped drain, needle-punched or spun bonded geotextile should not be used in a pipe wrapping application without careful design consideration due to the much-reduced surface area. In this instance, we recommend utilising a knitted filter sleeve material, which provides a significantly higher flow rate.

- Filter Sleeve shows 16x higher flow than spun bonded fabric in pipe applications with silty sand.

- Best suited for applications where trench-wrapping isn’t feasible or surface area is limited.

- No soil piping observed in any test, indicating robust filtration performance.

- Knitted Filter Sleeve recommended over needle-punched or spun bonded fabric for pipe wrapping.

References

ASTM D5101 Standard Test Method for Measuring the Filtration Compatibility of Soil-Geotextile Systems (Gradient Ratio)

Cirtex-Gradient Ratio Testing-D5101 (2025-01-13 FIN) TRI Laboratories

Designing with Geosynthetics by Dr RM Koerner

FHWA NHI-07-092 Geosynthetic Design & Construction Guidelines