Worcester Street, Christchurch – ChipSeal Resurfacing Test

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

As part of the general maintenance and upkeep of Christchurch City Council’s Road Network, the existing pavement surface along Worcester street consisted of a mix of asphalt and chip seal, with significant cracking caused by the underlying concrete base. As the principal maintenance contractor for the area, HEB Construction was tasked with identifying a long-term solution that not only addressed the existing degradation but also aligned with council expectations around innovation, sustainability, and cost-efficiency.

Rather than defaulting to traditional resurfacing methods, HEB saw an opportunity to trial ChipSeal Grid, a new reinforcement and waterproofing solution as part of a proactive pavement preservation strategy. The selected 400-metre stretch of Worcester Street would serve as a live test site, with performance monitored over time.

DESIGN

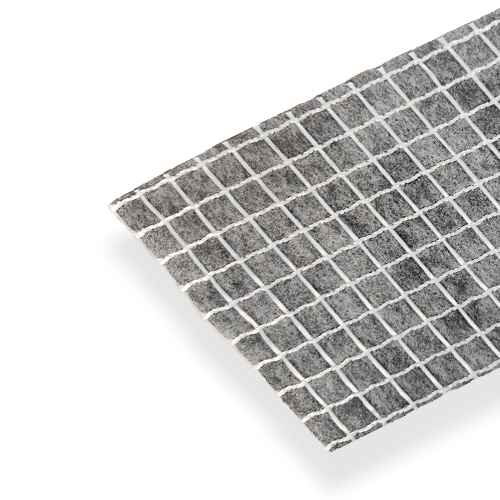

ChipSeal Grid is a high-performance geosynthetic designed specifically for reinforcing chip seal road surfaces. It is placed directly within the chip seal layer, where it performs two key functions: reinforcement, by distributing tensile stresses across a broader area to resist reflective cracking; and waterproofing, by integrating with a membrane seal layer to limit moisture ingress into the pavement layers below.

For the trial, ChipSeal Grid was installed across the full width of a 400m section along Worcester Street. The objective was to test the performance of ChipSeal Grid under typical urban traffic conditions, particularly focusing on crack resistance, water ingress prevention, and overall surface durability over time.

INSTALLATION

Installation of ChipSeal Grid is straightforward and integrates well with existing chip seal processes, minimising disruption and cost. The surface was thoroughly brushed clean to remove debris and prepare for sealing. No milling or heavy preparation was required.

A bitumen emulsion membrane seal was then sprayed over the cleaned pavement, serving as both a tack coat and a waterproofing layer. The ChipSeal Grid was placed directly into this emulsion, ensuring good adherence, with the specified overlap between the two rolls.

Following the grid installation, a traditional two-coat chip seal was applied. This involved a first spray of polymer modified emulsion binder followed by loose chip, which was then rolled to embed the aggregate. A second layer of polymer modified emulsion binder and chip was then applied and compacted. The entire process used conventional chip seal equipment, demonstrating the product’s ease of integration into existing workflows.

By incorporating ChipSeal Grid into the reseal treatment, HEB achieved a reinforced, water-resistant surface. The grid is expected to significantly delay the onset of cracking, extend the life of the chip seal, and reduce maintenance frequency and cost over time.

This trial also allows for a controlled comparison with untreated pavement. The long-term performance monitoring will provide Christchurch City Council and HEB with valuable insights into the effectiveness of ChipSeal Grid and its potential for broader network adoption.

The Chipseal Grid provided the following benefits to the project:

Improved pavement lifespan

Enhanced waterproofing

Cost-effective maintenance solution