Cambridge Road Slip Repair – DuraMesh® MSE Wall

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

With mitigating factors such as poor drainage, increased water filtration, tree removal and previously placed ungraded fill, this 24m wide section adjacent to Cambridge Road slipped 40m down the bank during an extreme weather event. With the slip only 0.5m from the edge of the road seal, Tauranga City Council required a retaining solution that would blend in with the 60°-70° slope of the surrounding land, as well as have adequate drainage to counter the original cause of the slip.

With other proposed options including Sheet Pile and Anchored Timber Pole walls, the recommended remediation solution was to construct a Mechanically Stabilised Earth wall using DuraMesh panels. This would prevent further regression of the slip, provide necessary support to the road, and could be constructed quicker and more cost-effectively than the other options.

DESIGN

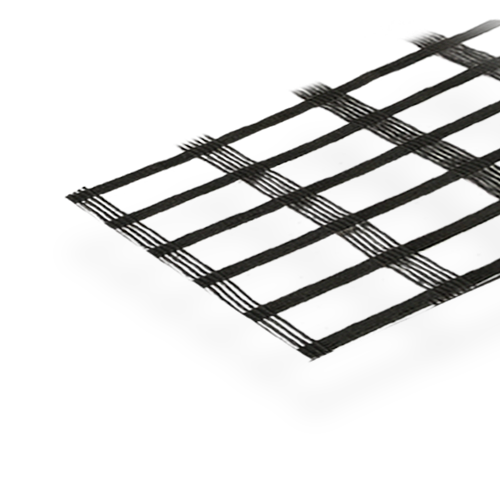

A staggered, 10.2m high, 24m wide tiered green-faced DuraMesh MSE wall was designed using StrataGrid reinforcement strips, incorporating two 70° sections with panels and an upper 45° DuraGreen MSE section without panels. Predominantly straight, there was also an angled return to meet the edge of the surrounding land. To support traffic, a minimum 12kPa surcharge loading would be required. The wall would also have a safety fence running along the top beside the road.

To meet the original slope angle of the land before the slip, the three wall faces will be separated by a 3m and a 1.5m at section. To help with drainage, DuraFlow drainage composite will be placed between the cut face and the engineered fill. BioWool is to be placed behind the panels as well as a 200mm layer of topsoil, so that vegetation can occur

INSTALLATION

All slip debris and loose fill material was removed via an accessway below the site. With traffic on Cambridge Road reduced to a one way lane and rerouted coming the other way, access within the site was limited to a thin section adjacent to Cambridge Road.

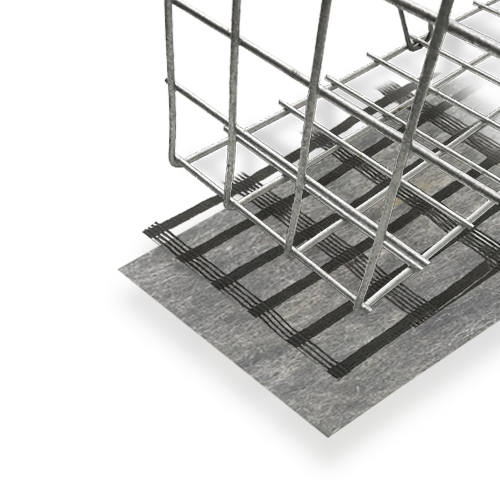

A 70° batter was cut into the slip face, stepped out to match the placement of the DuraMesh wall, then lined with DuraFlow drainage composite. The entire wall was stabilised using StrataGrid reinforcement strips, extending back 6m at 250mm lifts, with a slope geogrid overlap of 1.5m between each layer of compacted engineered fill. As DuraMesh construction with StrataGrid is strong enough to work on once compacted and tested, a steep access track was created to the lowest level so contractors could use the reinforced zone as their platform while they constructed the wall.

The DuraMesh panels were hogtied together, with BioWool placed directly behind the panels. BioWool is the preferred cloth to use behind the panels when vegetating, as the support pins are easily pushed through to attach to the outside cages. The 200mm layer of topsoil was simply placed between the engineered fill and the BioWool, with planting su ciently watered until established.

To further manage stormwater, new road kerbs and channels were installed on both sides of the road, with all collected stormwater directed to the bottom of the slope via a 300mm PVC pipe attached to the exterior of the wall. A bubble-up chamber and a rock riprap channel were also installed for added protection.

It was the first DuraMesh wall that Heavily Soiled Earthworks had constructed, so Cirtex were always available onsite offering construction assistance. They’ve done a great job, finding it easy to install and are looking to use DuraMesh as an MSE solution in further construction.

The DuraMesh and StrataGrid provided the following benefits to the project:

- The reinforced zone can be used as a work platform once compacted and tested

- Can be installed within tight work spaces

- Quick and cost-effective to construct