Coronation Road Subdivision – MagnumStone™ Gravity System

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

As part of developing Auckland’s Māngere Bridge, this brand-new subdivision will introduce 227 architecturally designed terrace homes. The subdivision was initially designed with timber pole retaining walls, but during construction, contractors Rohits Civil hit embedded rock, preventing their ability to drill holes deep enough for the timber poles. This impacted the program so to keep construction progressing on time, and to avoid further consenting issues, some alternative retaining wall design methods were sought.

During the course of investigating different construction methods, the design engineer registered for the MagnumStone Design Software, interested in the opportunities it offered around building a retaining wall without the need for drilling. Cirtex’s technical sales team then connected with the engineer and Rohits Civil, offering advice on designing and building with MagnumStone.

DESIGN

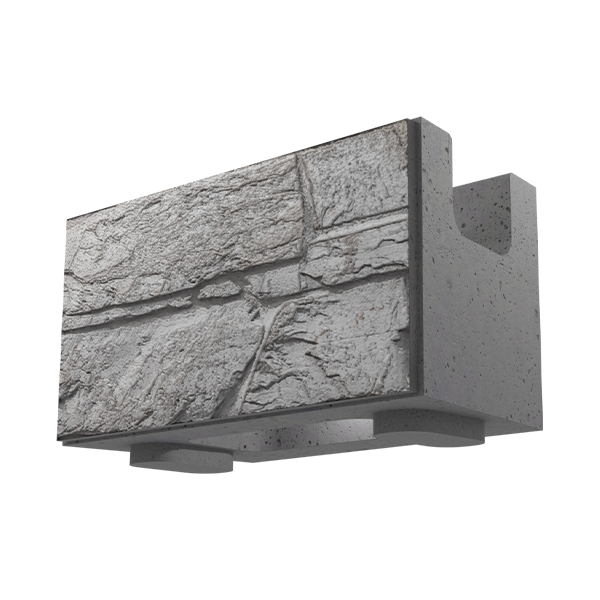

Rohits Civil required a robust retaining wall system that would sit on top of the already excavated soil structure. MagnumStone’s gravity wall system removed the need for more piling. Fitting within the same space required to cut the soil face, drill, install and backfill the piled retaining walls, the MagnumStone system offered construction advantages that would get the development back on track. Adding to the speed in which the two wall designs were assessed, Rohits Civil were quickly able to make up for lost time.

Two MagnumStone tiered gravity walls with extenders were designed, the first being 100m long and 2.75m at its highest, the second being 152m long and 3m at its highest. The two tiered walls gave stabilisation and support to a road rising from the lower section to the upper level of housing.

INSTALLATION

There were several key aspects in successfully changing from timber-pole retaining walls to the MagnumStone system. One was the ease of switching design methodology, another was the relative speed of installation. As Cirtex manufacture and stock MagnumStone we were able to immediately deliver large quantities, with approximately two weeks passing between initially contacting Cirtex regarding MagnumStone availability, progressing through design, and product arriving on-site. After some initial on-site installation training from our team, Rohits Civil began constructing the walls straight away.

A standard MagnumStone block weighs around 630kg but has connections enabling it to be easily lifted and placed with the use of a crane or medium sized excavator, removing the need to manually handle the blocks. And, as they are comparatively much larger at 0.75sqm per face, construction speed increased, with the extenders also able to be lifted and guided into place.

From Rohits Civil’s point of view, the installation advantages and the positive impact on the project programme far outweighed the initial extra investment. With the design challenges of hard rock on site and consenting issues delaying the programme, by using the MagnumStone system, Rohit’s Civil were able to regain lost time.

The MagnumStone Gravity System provided the following benefits to the project:

- Speed of assessing the change in wall design

- Quick to install and safe for workers

- Fast supply of blocks due to being locally manufactured