Division Street Resurfacing – HaTelit

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

In 2019, Christchurch City Council contracted Fulton Hogan to do a full pavement and urban upgrade of Riccarton Road. During construction, they identified that the pavement on an extension of Division Street, which acted as a main service lane to Westfield Riccarton shopping mall, was in poor condition and had dramatically failed.

Division Street was not part of the original contract, but due to the large amount of heavy vehicle use and concern over stakeholder engagement and public perception, Christchurch City Council also desired this small stretch of road to be upgraded, allowing another 3-6 months’ extended usage during Riccarton Road’s reconstruction before more budget could potentially be provided for a full upgrade.

DESIGN

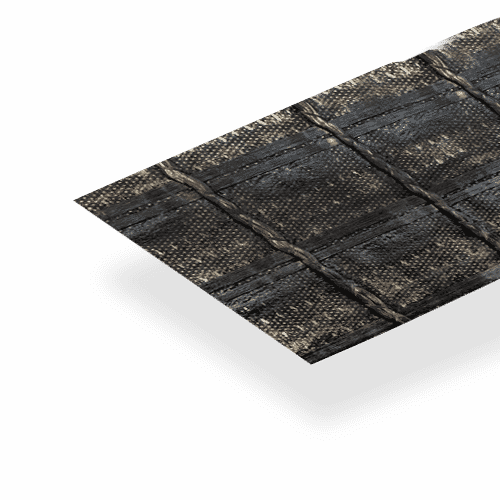

Fulton Hogan agreed to lightly mill the existing surface then overlay 40mm of asphalt AC14 but owing to the extreme number of cracks and large deflections, they weren’t confident that this would last the 3-6 month Riccarton upgrade. Instead, Fulton Hogan proposed the inclusion of HaTelit C 40/17, claiming a layer of this reinforcing geogrid would potentially extend the use of Division Street a further 6-12 months before more permanent restoration work was required.

Cirtex were on hand to guide the HaTelit installation. Ground conditions were so poor, deflections could be seen in slight bow waves created by the trucks’ tyres as they sprayed and laid out an initial membrane seal. Acknowledging that these weresub-par conditions and not in line with the recommended surface preparation, this was deemed to be a ‘band-aid’ solution, designed for months, not years, of reprieve.

INSTALLATION

The HaTelit geogrid was laid directly onto a freshly applied bitumen tack coat layer on top of the membrane seal, despite a large number of undulations. Some wrinkles also accumulated in the material where it couldn’t bond to the tack coat below, but due to budget and time, the consensus was that this was the best that could be done on the night. The road was finished with a 40mm compacted layer of asphalt.

Nine months after completion, even with constant heavy vehicle use, there were no visible crack or failure points. It’s now 2023, and in what was meant as a short term 6-12 month fix, HaTelit C Reinforcement Geogrid provided a solution that hasn’t failed almost four years after completion. By installing HaTelit C, despite the extremely poor ground and less-than-ideal laying conditions, Fulton Hogan not only hugely extended the asset life of the road but saved Christchurch City Council considerable money by not having to mill and overlay after 6-12 months later.

This creates a clear case to the industry as to why HaTelit C should be considered in far more situations for pavement rehabilitation projects around NZ and extending asset life