Dyers Pass Road Safety Improvements – MagnumStone™ Soil Nailed System

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

On a tight, winding section of Dyers Pass Road linking Cashmere in Christchurch to Governors Bay, Christchurch City Council in conjunction with NZTA were looking to improve safety conditions by widening the road for motorists and the large number of recreational users.

An original design using gabions looked to trim the inside bank of the road, then widen and support any shoulders with the inclusion of a low guard-rail. As Higgins began the job, they hit unusual ground conditions beneath the road, causing large delays to the project. With a fixed date that the road had to be completed by, Higgins required an alternative method of building the retaining structure and guard wall. To get construction moving, they turned from gabion to MagnumStone.

DESIGN

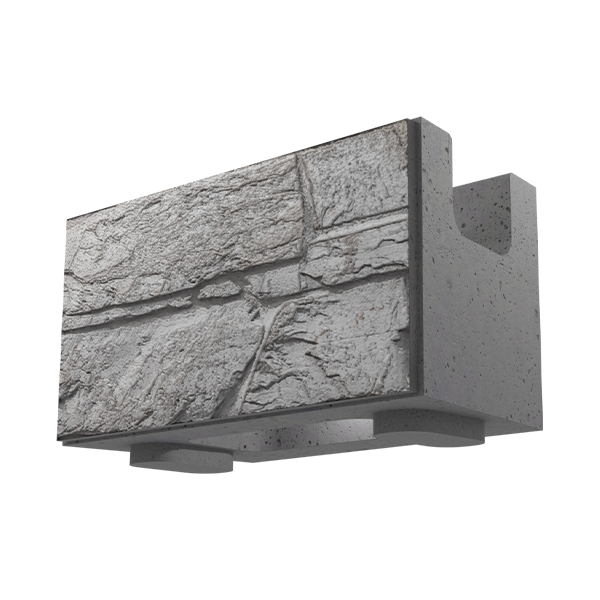

As MagnumStone was relatively new to New Zealand at the time, Cirtex worked closely with GHD and Higgins, looking at the technical aspects of a full design change from gabion to the MagnumStone system. In parts, the road was to be widened 1.5m either side from the outside white lines, either cut into the rockface, or supported by a MagnumStone wall. It was a low-key design, ranging from two to three blocks high, but due to the poor underlying conditions, the soil beneath the road required underpinning. The soil anchors were designed to attach between the MagnumStone blocks, helping to stabilise the ground beneath the road.

A crash barrier was also to be inserted directly behind the blocks. With concerns that if a car did crash into the barrier, individual blocks could pop off during the impact, so extra reinforcement was designed to sit inside the hollow core of each block, with concrete to be poured into the hollow once Higgins had terminated the soil anchors. Not only would this lock the anchors in place, but it would create lateral strength by tying each individual MagnumStone block together.

INSTALLATION

Over the course of the project, Cirtex produced approximately one thousand MagnumStone blocks. Cirtex staff also supplied onsite training, with much of the installation done at night to reduce road closures during the day. By working at night, Higgins could lay a similar volume in one night with MagnumStone as they could in almost a week with gabions. MagnumStone not only reduced the manpower, but also the risk of injury during installation as all MagnumStone blocks are lifted into place using a small excavator. The low height and strength of the MagnumStone wall also meant Higgins could backfill straight away. With no open excavations, Higgins could quickly reopen the road to daytime traffic without it having to be sealed.

MagnumStone’s maneuverability also meant flexibility for contractors on-site. Large swathes of the wall could be constructed without worrying about building in conjunction with the anchor contractor. The top MagnumStone blocks could simply be lifted out, allowing the soil anchors to be driven in precisely where they needed to be, before the MagnumStone block was repositioned and locked in place. Once the wall was finished, the block faces were then coated with a natural looking waterbased coating to help them blend in with the local landscape.

Readily available, safer and faster than gabions to install, the use of MagnumStone on the Dyers Pass project is a prime example of low-risk shoulder widening work that happens all around NZ. By shifting to MagnumStone, Higgins shaved several months off their programme. This saved a large amount of traffic management but owing to the concentrated stakeholder engagement regarding the project, it also satisfied Christchurch City Council’s residents and recreational users.

The MagnumStone system provided the following benefits to the project:

- Natural aesthetic qualities

- Flexible features mean contractors can work around each other during installation

- Quickly assessed design changes from other construction methods