Godley Quay Pavement Resurfacing- HaTelit® C

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

On the 18th and 19th of March 2023, SailGP came to New Zealand for the first time. This high-speed, high-tech yacht racing series has captured the world’s attention ever since its introduction in 2018. With the eyes of the world upon Lyttleton Harbour, Christchurch City Council desired an upgrade to Godley Quay, the main road commuting viewers and contestants to the purpose built, temporary arena and the ITM Grand Prix Race Village at Naval Point.

Godley Quay’s road surface however, was in a greatly degraded state, having been used for heavy industrial traffic for many years. Areas of the pavement rest on reclaimed land, giving engineers no real understanding of what the current surface was built on, but as spectators and participants of the race were to be shuttled to the village using this road, Christchurch City Council desired a smooth, pleasant ride for local and international visitors coming to Christchurch for the event.

DESIGN

Looking for a cost-effective solution that would see them through the event and beyond, Christchurch City Council was offered three resurfacing options. The first option was to completely rebuild the road, however a full dig out and reconstruction upon such a shallow surface proved to be too costly.

The second was to simply mill off the current surface and reseal. Due to the extent of the deterioration and the constant heavy vehicle use, there was concern whether this option would remain stable leading up to or much beyond the event.

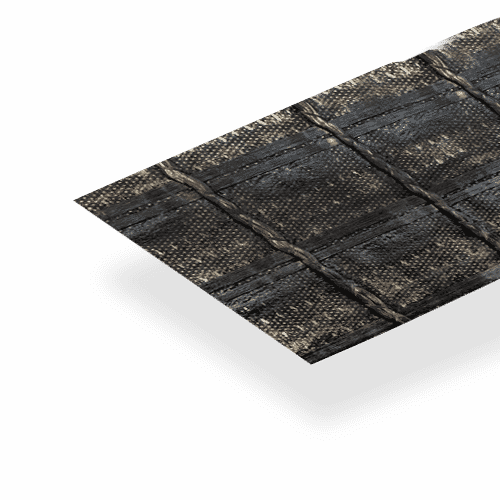

A third proposed option was to mill the surface layer back, then lay HaTelit C reinforcement grid between two bituminous layers. HaTelit C counters any reflective cracking rising from the lower, original road. With a track record of maintaining a stable, smooth resurface and greatly extending the life of a road once installed, the use of HaTelit C between the old and new surfaces proved the ideal choice for resurfacing Godley Quay and realising Christchurch City Council’s vision.

INSTALLATION

After the original road was milled down, a layer of GridTex was laid upon the soil layer, then covered with a 150mm Cement Treated Basecourse layer. This prevented fines migration and helped interlock the subbase with the CTB layer. Once rolled and cleaned, crews made preparations to install the rolls of HaTelit C at night to help mitigate the extreme temperatures during the day. If laid when it’s too hot, the HaTelit layer may not properly bond with the tack coat and may pull when the wheels of the roller pass over. Once set, two asphalt layers of AC20 and AC14 were placed and rolled to complete the new road installation.

Because access was still required by residents and commercial vehicles, installation was split over two nights, with one side of the road being laid down on the first night so traffic could pass through, and the other side of the road installed the following night. To create a seamless connection between the two sides, a rigid line was cut into the first installation where the seams would join, essentially down the middle of the completed road. This allowed for a clean connection when the second run of HaTelit and asphalt was placed.

By using HaTelit C, Christchurch City Council not only has a smooth road surface that will be enjoyed by the multitude of visitors coming to watch the SailGP event, but an enduring pavement surface that will service industrial and cultural events for years to come, opening up Naval Bay for future endeavours.

The HaTelit C system provided the following benefits to the project:

- Counters reflective cracking from rising into the upper layers

- Can be placed over an original/damaged road once milled

- Greatly extends the life of any repaired or newly built road