Kōpaki Bridge Abutments – MagnumStone™

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

Spanning the North Island Main Trunk Railway Line on State Highway 30, the existing timber, single-lane Kōpaki overbridge has come to the end of its life and needs replacement. A new dual-lane overbridge will be constructed, with the bridge approaches on SH30 and the entrance to Kōpaki Road realigned to allow better visibility for turning traffic. As the new piled bridge is an independent structure, Downer approached Cirtex about creating two bridge abutments that would extend and lift the road to meet the bridge structure, without impeding the Main Trunk Railway Line during construction. With the old bridge now limited to vehicles under six tonnes, the new bridge and abutments needed to take the weight of all trucks, including high productivity motor vehicles (HPMVs) when complete.

DESIGN

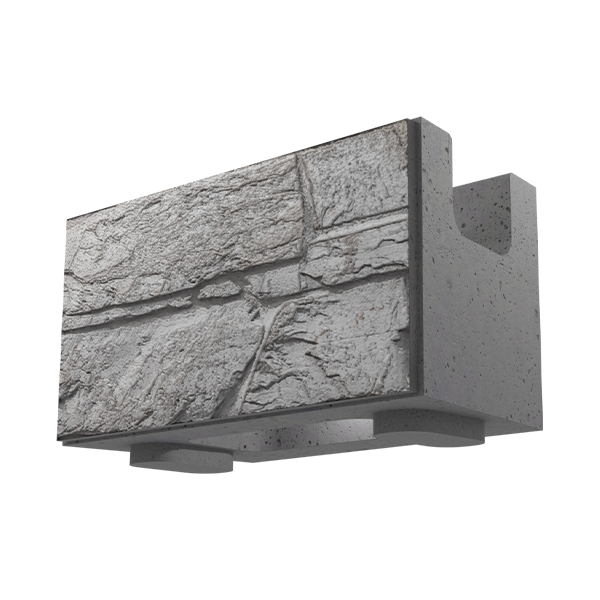

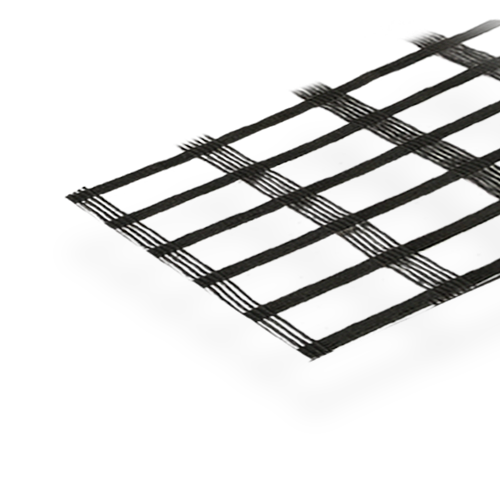

Working alongside CMW Geosciences, Cirtex conceptualised some initial design options. A retaining block structure with high-strength geogrid tieback was the preferred choice, with MagnumStone’s adaptability and design features making it perfect for the project. Its standard 97.6° batter, along with connecting lugs, meant precision when raising the abutments to meet the bridge structure above. Being manufactured in Thames, it was also readily available. As the abutments were designed to lift the road to meet the bridge rather than take the load of the bridge itself, CMW Geosciences opted for a MagnumStone wall design with a friction connection. Each 650kg block rests upon a layer of StrataGrid, which then ties into the reinforced zone within the abutment. Two tiered walls of approximately 45 m in length were designed. The upper eastern wall was approximately 4 m high, with the lower western wall approximately 5 m high. Both included curves and a 90o corner.

INSTALLATION

With piling complete and the headstock poured, Downer began work on the upper eastern abutment first. Once the contractors had prepped the foundation, the team at Cirtex gave onsite training of MagnumStone and StrataGrid installation. As MagnumStone is designed to be lifted and installed with the use of a light excavator, work could be conducted from ‘within’ the abutments. This made construction faster and easier as the reinforced walls extend right to the main bridge piling, rising to meet the edge of the headstock. This also meant workers remained clear of the railway. Contractors needed to make sure MagnumStone’s 97.6° batter met perfectly with the steel rods extending from the bridge structure. The lugs within the MagnumStone blocks helped guide that placement, as contractors knew exactly how much recess was required with each additional layer. Once complete, work on the lower western abutment began. Despite being in an isolated location, Cirtex was able to manufacture and deliver large quantities of MagnumStone to site. The old bridge was used to get access over the railway line from one side of the site to the other, but it will be removed once the new bridge is open to traffic. The new modern bridge design will serve the next generation, giving safer and greater access to the Kōpaki region.