Laurence Stevens Drive, Auckland Airport – HaTelit® C

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

With road and parking projects put on hold during the pandemic, Auckland Airport have restarted three projects – Park & Ride South, Laurence Stevens Drive upgrades and Te Ara Kōrako Drive extension. Their aim is to accommodate future growth, with more than 40 million passengers and 260,000 flights a year expected by 2044, doubling the number of passengers the airport currently handles today.

As about 40 per cent of traffic into the airport precinct comes from the south, improvements to Laurence Stevens Drive and Hape Drive are a key part of their plan to build a resilient roading network around Auckland Airport. This will include the construction of a terminal bound T3 lane, including the AirportLink that connects the Puhinui Station Interchange, and the Park & Ride South bus connection.

DESIGN

The proposed surface and facilities upgrade includes a small section of Puhinui Road to the new intersection with Tom Pierce Drive, then along Laurence Stevens Drive until it meets George Bolt Memorial Drive. Laurence Stevens Drive will be widened to add an inbound high-occupancy vehicle lane. There will be improvements to four existing bus stops as well as adding two more bus stops. There will also be new, safe pedestrian crossing points, wider and extended footpaths and upgrades to street lighting and underground services.

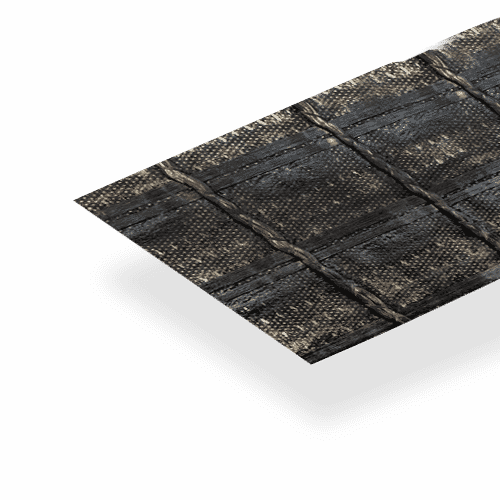

To increase the asphalt design life over such a complicated patchwork of new and existing pavement surfaces, WSP turned to HaTelit C Asphalt Reinforcement Geogrid as a bridging layer that would prevent reflective cracking, creating one seamless new surface. With long stretches of road, slight curves and roundabouts to cover, an efficient rollout design was created to get the ideal placement of each roll to mitigate any wastage along the approximately 1.5km stretch of road.

INSTALLATION

The full road repair was done in stages, allowing for traffic to continue to and from the airport. Old surfaces that were to remain were milled back, with new pavement surfaces prepared to the same base level, ready for the first asphalt layer, over which HaTelit would be laid. Where existing concrete surfaces remained, a thin layer of asphalt was laid over the top, allowing a continuous run of HaTelit C. As concrete has a higher pH level, a slightly different product, HaTelit XP would normally be placed directly on top, but to allow quicker installation of the reinforcement geogrid, these concrete patches were covered first.

HaTelit is placed between two bituminous layers. Once the new and old surfaces had been levelled, an initial layer of aggregate was placed and covered with a specified, even layer of bitumen. Supplied in 4 or 5m wide rolls, HaTelit can either be rolled out by hand or with the use of a telehandler with a specially designed laying frame. It can be cut and lifted into place, allowing for slight angle adjustments. It is intended to remain free of wrinkles, so it is important to design the most economical layout of straight lines. Once all new and old surfaces are covered, the final surface asphalt layer can be placed.

With HaTelit bridging old and new surfaces, Auckland Airport know they will have a long-lasting pavement network that will encourage more foreign and domestic visitors.

The HaTelit C provided the following benefits to the project:

- Quick and easy to install

- Greatly increases the longevity of pavement surfaces

- Reduces reflective cracking, even when placed directly over old pavement