Robins Road, Queenstown CBD – MagnumStone™ Gravity Wall

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

Stretching from Arthurs Point to downtown Queenstown, a new 3.5m wide shared path and cycleway is being constructed along Gorge Road. The path reaches Queenstown’s CBD adjacent to the Recreational Reserve, where Robins Road merges into Camp Street. An existing stacked rock wall supports the current small footpath, but with the road surface being widened to accommodate the shared path, it was deemed the rock wall was insufficient to carry the extra traffic loading.

A new retaining wall was required in the reduced space between where Camp Street curves into Robins Road and the car park area next to the Queenstown Recreational Reserve. This would allow the new surface to simply be placed over the top of the original rock face wall without the need for further excavation and complete closure of the road.

DESIGN

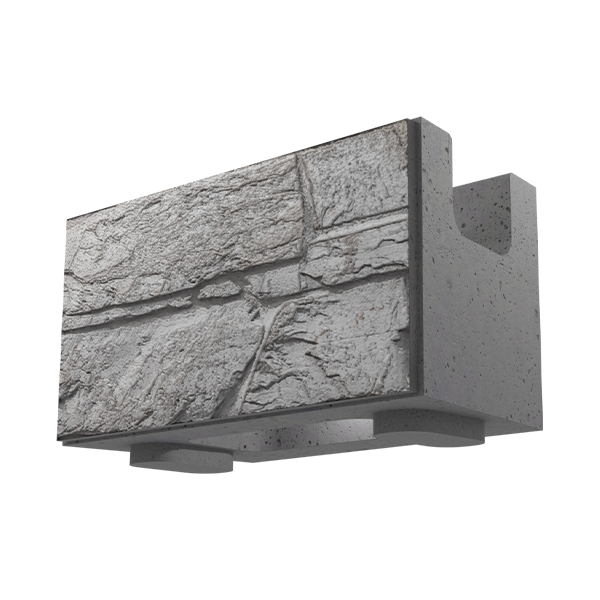

Two separate walls were originally designed. The first was a 40m long, MagnumStone Gravity wall retained to height of 3.6m, running from the bottom of Camp Street to where the road rises and curves into Robins Road. A 94m timber pole wall retained to an average of 1.5m had originally been proposed to continue along Robins Road, but the benefits of MagnumStone’s 100-year design life, the ease and speed of installation, as well as its stone facia to match Queenstown’s aesthetics, meant the MagnumStone gravity design was extended to include this section.

The design of extender blocks and near vertical wall face also meant minimal excavation of the main road during construction. Services would be placed behind the wall within the hollow core. With the new surface placed right to the edge of the wall, a handrail would also be inserted into the top of the wall.

INSTALLATION

Having reduced Camp Street and Robins Road to one lane, the area was cleared of debris before a granular leveling pad was laid. By changing from a timber pole wall to the MagnumStone system, weeks were shaved o the construction programme, avoiding the use of large machinery to drill holes into the ground. With a level surface, the blocks and extenders were easily placed using an excavator, with units being delivered to site from the manufacturing facility in Christchurch early in the morning before traffic started to build. Ease of handling meant quick construction, with the two walls being built either side of a small, existing building.

A drainage aggregate fill wrapped with geotextile was placed into the hollow core and over the extenders as each layer rose, with the handrail placed into the hollow core of the top layer of MagnumStone and secured with a concrete pour.

Combining beauty with functionality, MagnumStone gave QLDC an engineered solution that mirrored the majestic mountains surrounding Queenstown, with the shared pathway offering adventurers and tourists a new way to experience the road to the Shotover River and Arthurs Point.

The MagnumStone system provided the following benefits to the project:

- Can be constructed within a tight space

- Safe and fast to construct

- Removes the need for drilling rigs and larger machinery

- Fast and cost effective solution