Rodin Cars Racetrack Resurfacing – HaTelit®

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

With a passion for racecars, David Dicker had a vision. Develop and build production issue, replica Formula 1 cars that anyone could drive on a racetrack. After purchasing a high-country station in Wandle Downs, North Canterbury, David built an engineering and design facility, and over the years added two 2.5km test tracks. Unfortunately, poor initial surface preparation and the Kaikoura earthquakes meant surface reflective cracking and undulations began appearing in both tracks, becoming extremely dangerous when racing cars at 290kph.

Still only a few years old, the concrete and asphalt patchwork repairs were quickly deteriorating, yet the development of Rodin’s FZED racecar was gaining interest, so a long-term solution had to be found. After initial consultations, three options evolved.

- Completely excavate all existing track surfaces and build an entirely new track.

- Directly place a new 40-50mm overlay of asphalt over the track and cracks.

- Place a reinforcement geogrid on top of the existing track prior to a 40-50mm layer of asphalt.

DESIGN

With the extreme expense of option 1, and the shortcomings of option 2, where in a few years’ time they would be in the same position they were in now, option 3 became the obvious choice.

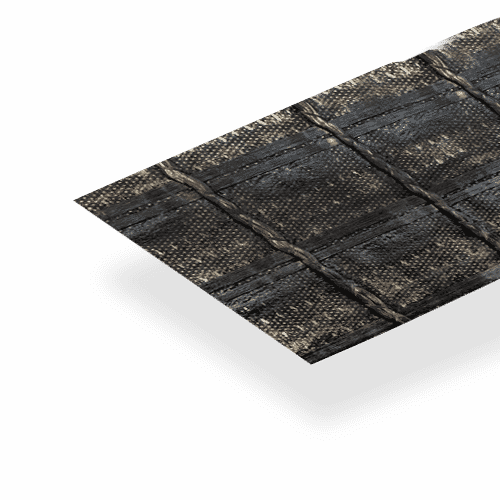

Rodin Cars approached Cirtex about HaTelit reinforcing geogrid. Cirtex specified HaTelit C40/17 for all areas where it was only in contact with existing asphalt, and because of concrete’s high pH levels, the patchwork areas would be covered with HaTelit XP 50.

Design considerations included the best roll width, laying direction on the 9m wide track and corners to efficiently reduce wastage, preparation factors to initially patch larger cracks and deformations, plus the tack coat to be applied before the HaTelit geogrid was placed on top.

Cirtex also developed a custom built installation frame with a built-in brush system designed for a forked machine. The brush system would press the product into the tack coat, getting a strong bond so it wouldn’t get picked up by any machinery that drove behind and on top of the HaTelit.

INSTALLATION

Custom manufactured in Europe and with shipping complications due to Covid, the order arrived just on time thanks to nationwide assistance by the Cirtex team, ensuring the geogrid was ready to install to meet Rodin Cars’ specified program.

February heat became an unforeseen factor. Track temperatures reached upwards of 60 degrees causing issues with the emulsion tack coat. Slow to break in these conditions, It bled through the grid causing it to stick to truck and roller tyres. Too hot to lay the geogrid in the day, the entire crew returned at night. In the cooler temperatures, the HaTelit was achieving a strong bond as desired.

JCL Asphalt started early in the morning to lay asphalt, running about 800m behind, but by the time they caught up, the day-time heat was starting to re-liquify the emulsion. Around several tight corners, JCL noticed some movement and minor bleeding of the emulsion through the HaTelit geogrid.

The decision was made to change to hot bitumen. Although a greater health and safety risk requiring a specialist crew, it provided a very strong bond the moment it was sprayed, allowing both crews to continue day and night.

After 7 days of installation, with over 5km of HaTelit installed and a 50 mm asphalt overlay complete, Rodin Cars once again had a smooth test track. HaTelit stopped any cracks from coming through, leaving David Dicker and the team at Rodin Cars focused on developing the new F ZERO, designed to be faster than a Formula 1 car.

The HaTelit Asphalt Reinforcement Grid provided the following features and benefits:

- Effectively counteracts reflective cracking

- Extends asset life

- Very easy and efficient to install

- HaTelit XP is alkali resistant

- An off the shelf product, or specific roll widths and lengths are available on request