- Menu

Civil Hub

Access a community driven forum, webinars on demand, technical drawings & advanced design software.

- ProductsFeatured ProductsGeotextilesGeogridsStormwaterReinforced Soil SystemsBlock Retaining SystemsGravity WallsGabionsSediment Retention PondsSite SuppliesSilt ControlDewatering & DrainageTurf MattingEarth AnchoringCulvert FlumesDrainage CompositesErosion Control MattingPermeable PavingImpermeable LinersPavement SurfaceGeocellsShear Lock®Concrete MattressesRock Bags

- Contact Us

Takatakahia Slip Repairs – DuraMesh® MSE Wall

Facebook

LinkedIn

Twitter

WhatsApp

Project Details

Contractor

Downer Paeroa

Client

NZTA

Engineer

Beca

Location

SH25a, Coromandel

Cirtex Regional Contact

Project Information

A large-scale storm event struck the Coromandel Peninsula late July 2017, leaving a trail of destruction in its wake. One location profoundly affected was SH25a where the Takatakahia stream embankment had suffered extensive scouring from rising water levels. The erosion significantly jeopardised the structural integrity of the state highway bridge above.

NZTA deemed this as a high-risk situation as further erosion of the bank would cause the bridge to fail. Traffic management was deployed immediately following the storm; the affected lane of the road remained closed until the completion of construction.

Design

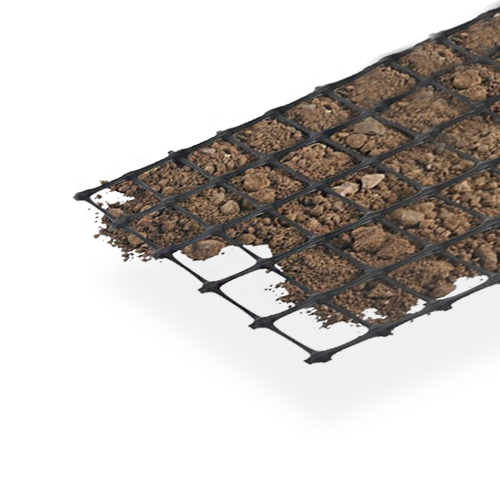

Cirtex worked closely with Downer and Beca to achieve the best possible outcome. Due to the critical nature of the site, our team was able to assist with identifying potential issues and suggest solutions, including the drainage of the exposed slope and length of the geogrid runs. It was essential to work quickly and transparently to ensure the products complied with the engineer’s design requirements, saving time and money during construction.

Installation

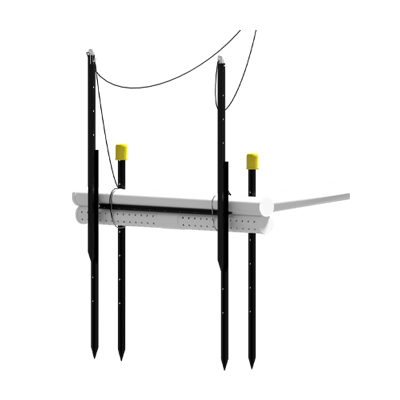

This slip repair was a very challenging project due to a very tight and problematic site. The speed of construction was a crucial factor requiring the need for the use of materials readily available. The DuraMesh solution presented saved the contractor weeks in downtime and related costs, mitigating the risk of the bridge failing.

During early stages of wall construction, technical staff met with Downer on-site to assist with installation procedures to ensure there were no delays to the construction program. Cirtex supplied specialist cutting equipment for the materials which safely increased the speed of installation. During the entire construction phase, the Downer team had access to technical staff to support when challenges and changes in design presented themselves.

The DuraMesh system provided the following benefits to the project:

- Speed and ease of installation

- Availability of product allowing fast and reliable supply.

- Cost-effective solution

- Aesthetically pleasing natural vegetated facing

Products used in this Project

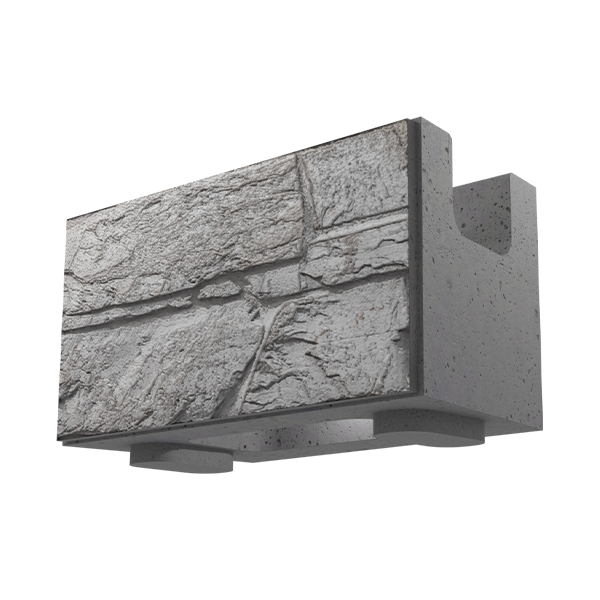

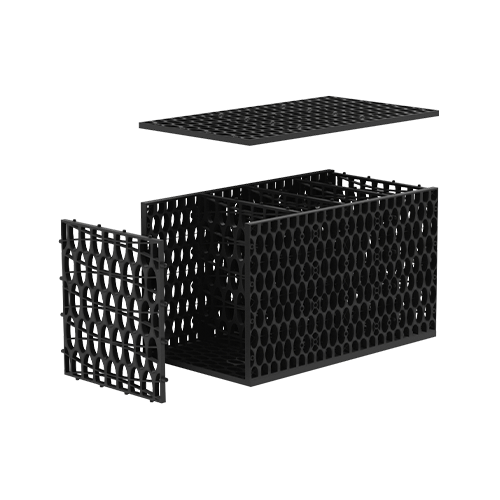

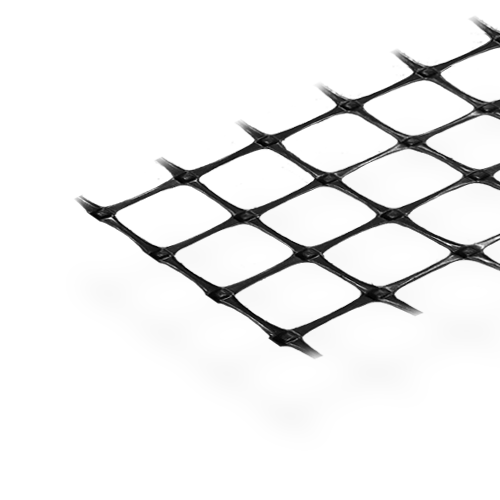

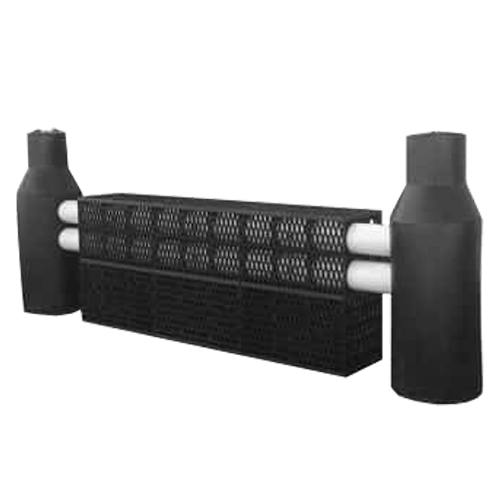

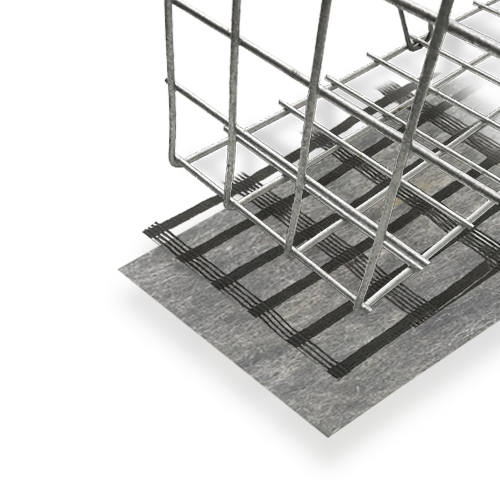

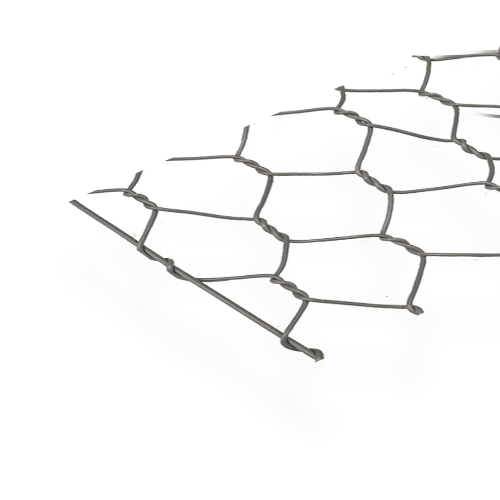

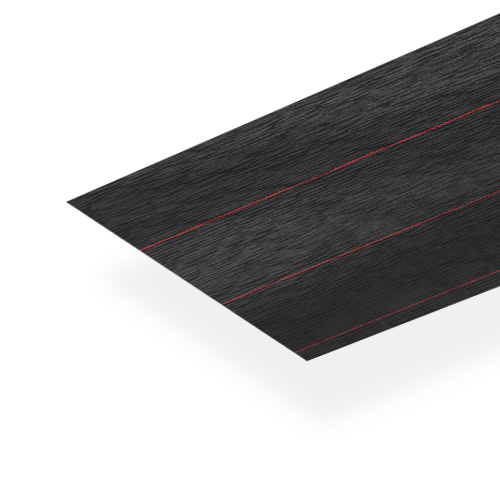

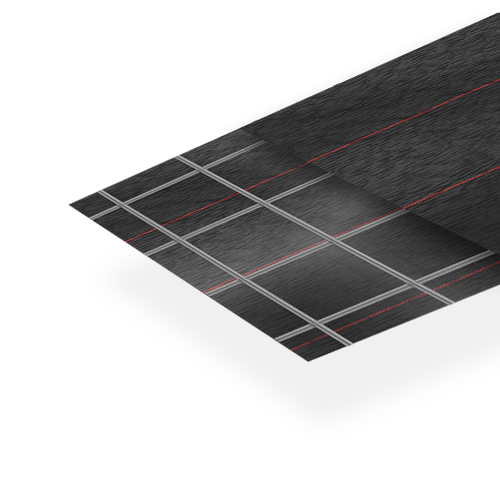

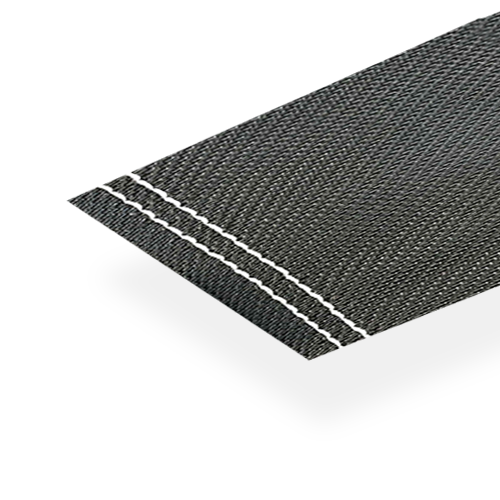

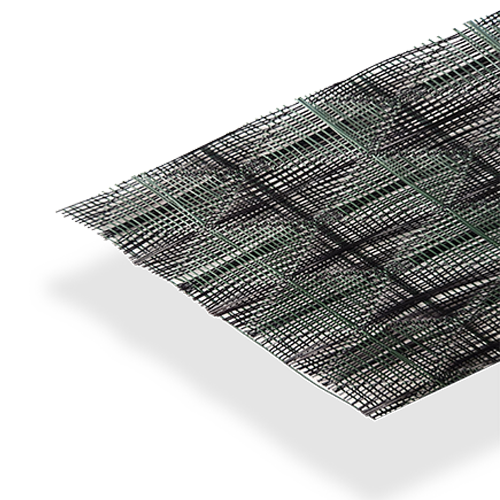

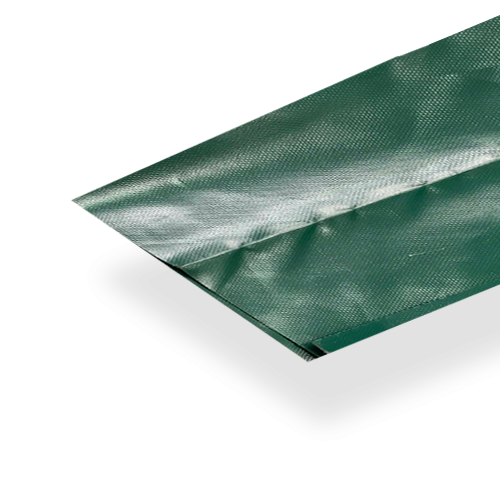

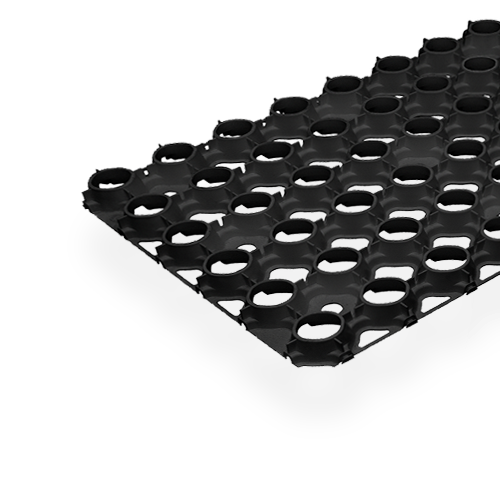

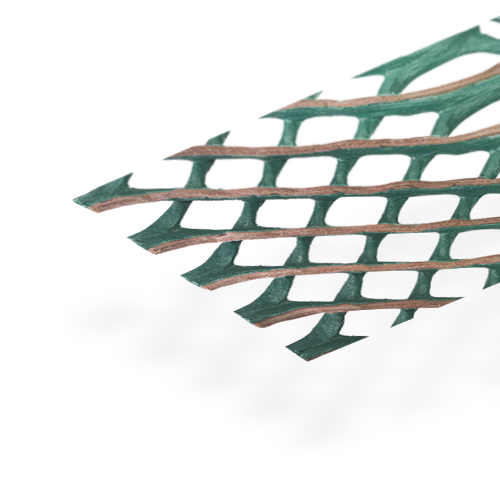

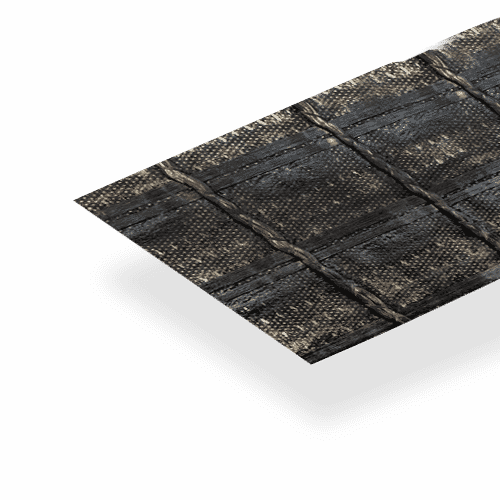

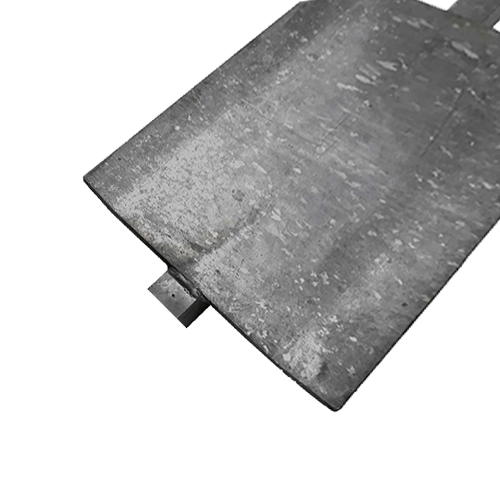

The DuraMesh® system is a proven, engineered, reinforced soil system allowing MSE...

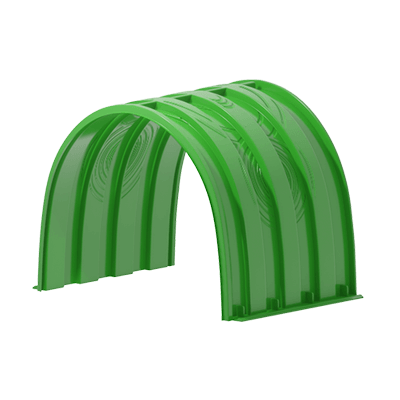

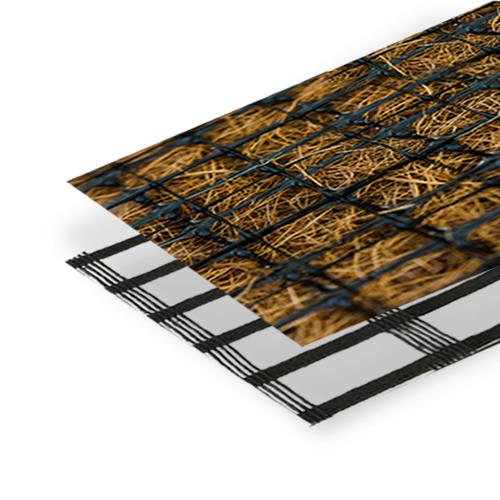

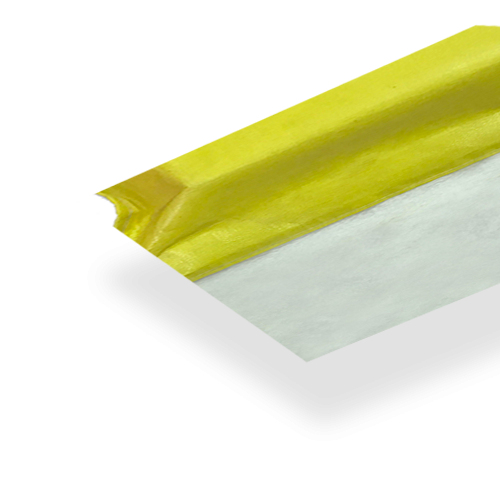

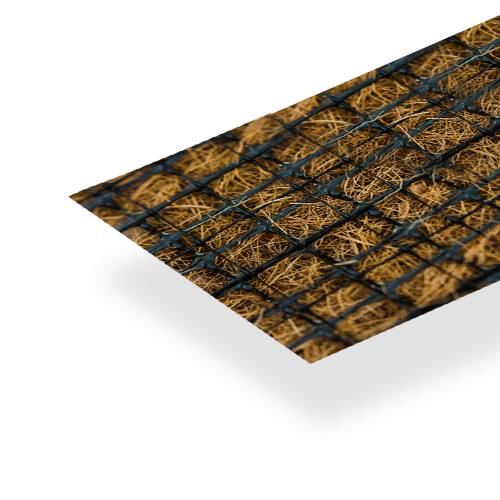

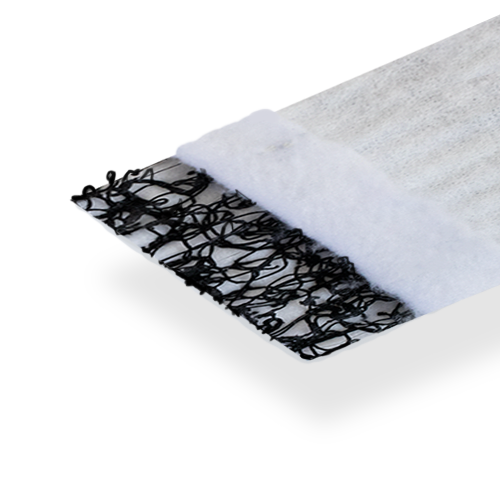

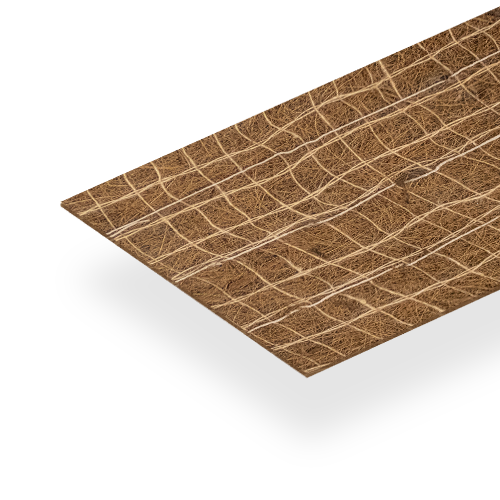

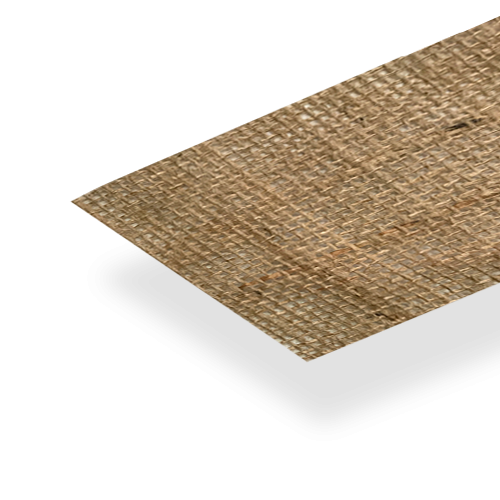

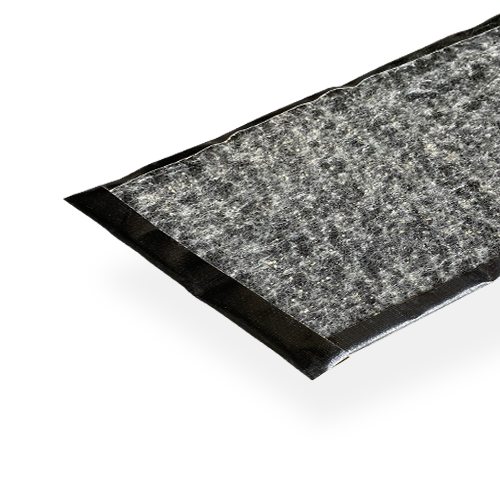

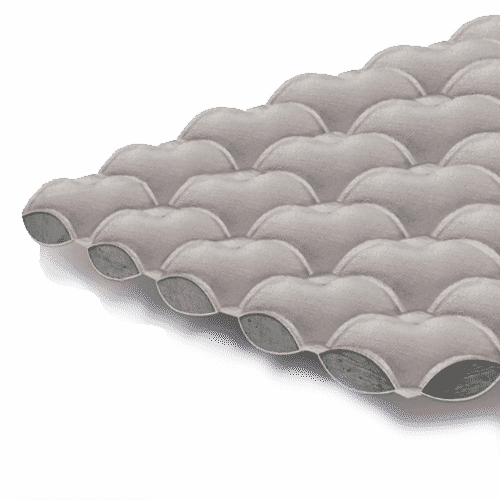

Cirtex BioWool is a biodegradable wool matting for erosion and sediment control...

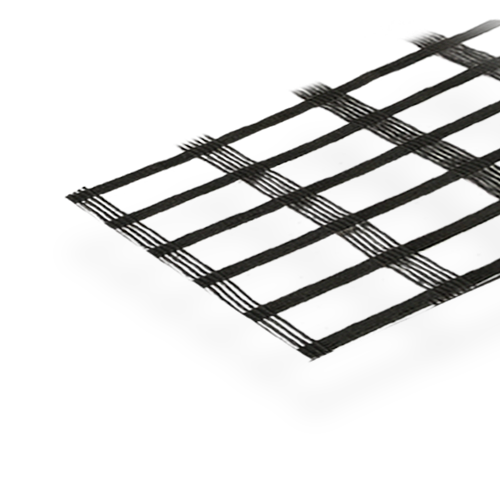

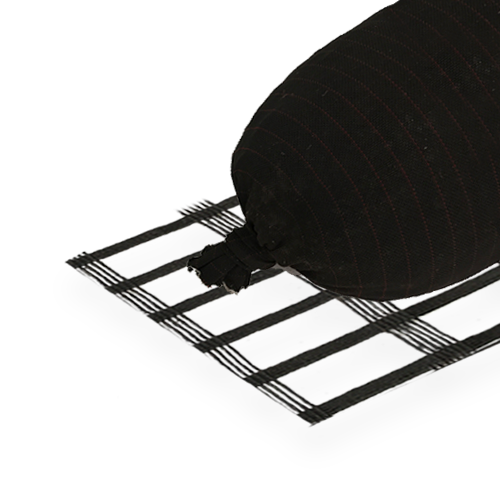

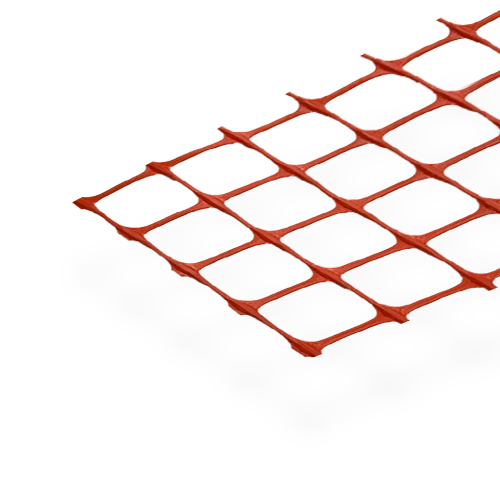

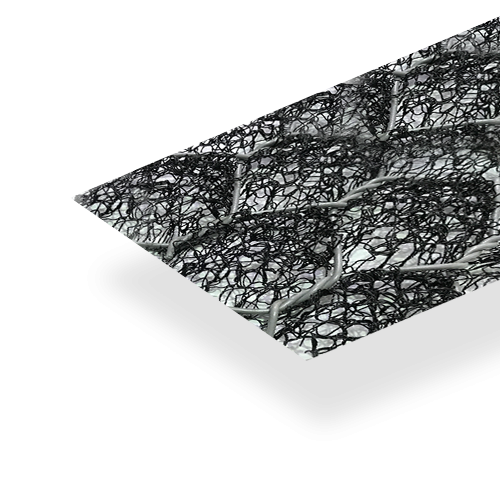

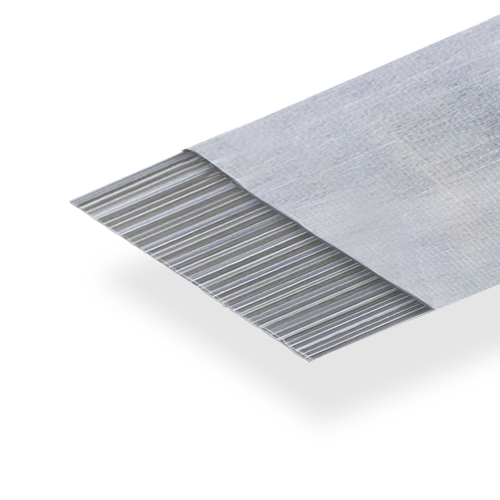

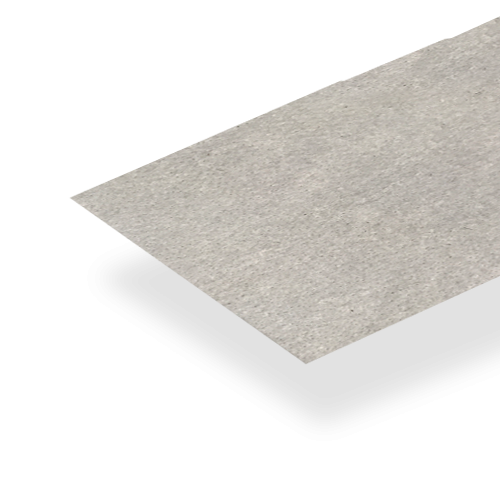

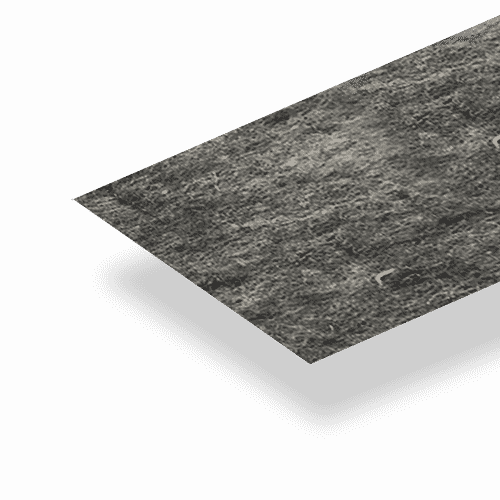

DuraForce AS series geotextile is manufactured and tested to exact quality standards...