Tapu Coroglen Road Slip Repair – MagnumStone™ Gravity System

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

With the closure of State Highway 25a, traffic accessing the eastern Coromandel Peninsula was forced onto alternative routes. While not designed for heavy traffic, large vehicles began using the gravel Tapu-Coroglen road as an alternative road, bypassing the longer routes via Coromandel or Waihi. Several extreme rain events, however, caused two major slips along the winding road, 10km and 13km inland from Tapu, again reducing the number of accessible roads into Coromandel’s east coast.

The smaller slip was successfully repaired using a DuraMesh MSE wall, but the larger slip had additional challenges, with the steep slope slipping away on a tight corner. As the Tapu-Coroglen Road winds through steep terrain, there was minimal space to work within. The engineers, HD Geo and Pinnacles Civil, sought a robust solution that could retain the existing road without the need for cutting deeper into the existing forestry area, as the upper slope also required retaining to prevent further slippage from above.

DESIGN

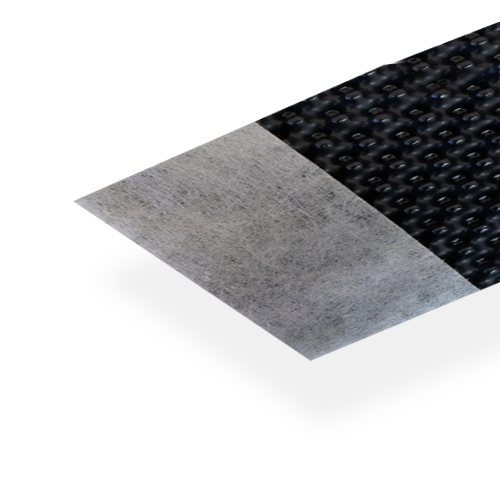

The outside curve on the upper slope was retained using a 42m timber piled wall lined with Armourflow Panel Drain. Armourflow allowed the wall to be built within the tight space between the road and the upper slope, removing the need for drainage aggregate.

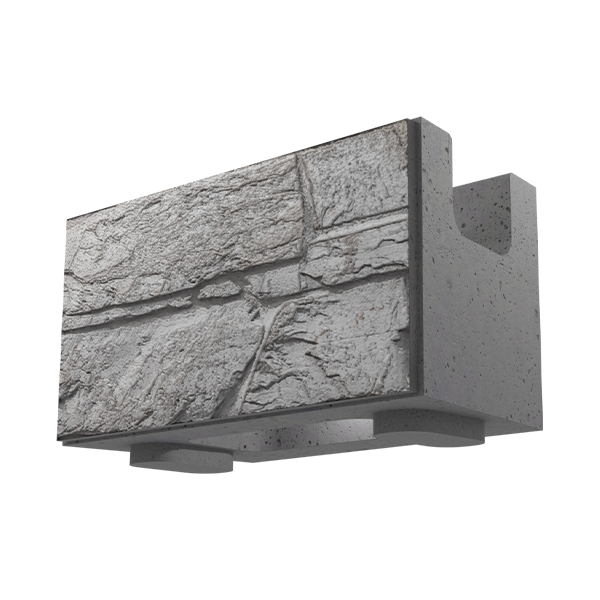

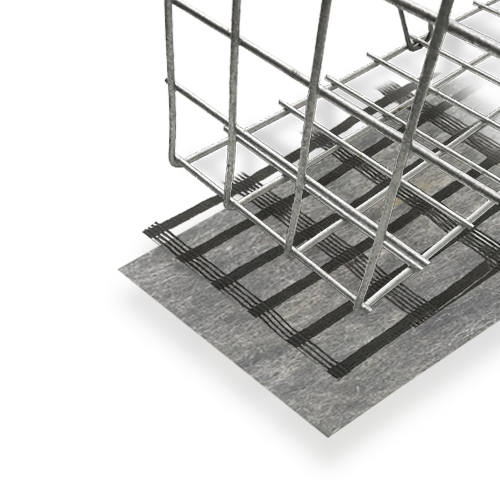

HD Geo designed a very innovative solution, consisting of a 36m long stepped MagnumStone Gravity Wall using the large extenders was designed to follow the tight curve of the road and rise to meet the contour of the surrounding land. Retained to a maximum height of 7.2m, the entire wall rose a total of 10m as it followed the curve of the road. To create the desired angle of batter, the wall was stepped back every second lift, with the front of the MagnumStone blocks resting on the back of the block below. While the lugs of each bottom layer of blocks sat within the hollow core of the block below, the lugs of each second lift would be pressed firmly against the back edge of the lower block. 110mm subsoil drains would be placed within the hollow core of the bottom layer of blocks as it stepped down the slope. Drainage aggregate would then be placed within the hollow core, with a 100mm 10MPa concrete infill sealing off the top of each exposed step.

INSTALLATION

Cirtex was regularly on site for installation assistance and advice. Once the initial debris was removed and the timber piled wall placed, access paths were cut into the lower slope. The first row of six blocks were placed on a level concrete pad, embedded 300mm into a founding layer of bedrock. The blocks were lowered using a longer chain from the top of the site, with Kelsey’s being able to collect additional loads of blocks from Thames to fit their programme, so as not to clutter up the tight site. An issue arose with the stepped-back blocks once the wall began to rise. Because of the tight angle of the curve, the lugs came out of alignment with the spaces between the extenders. After consulting with Cirtex’s design team to form a number of viable stability options, Kelsey’s were simply able to cut segments of the extenders away, leaving room for the lugs to slot into place.

Productivity was increased by using a Steel Wrist tiltrotator. Able to swivel 360, the Steel Wrist efficiency allowed drainage aggregate and fill to be accurately placed along the tight curves. A drainage bucket and hopper also allowed placement of aggregate within the MagnumStone block’s hollow core.

The upper slope bank coming from the Tapu side was hydroseeded to give extra stability, with the overslip to be planted in native vegetation. A new steel-post guard rail was also placed, and once the road was sealed, the Tapu-Coroglen road was declared open, giving safer access into the Coromandel’s east coast.

The MagnumStone system used provided the following benefits to the project:

- The use of extenders means installation can be done in tight spaces

- MagnumStone blocks can be delivered to fit any construction programme

- Quick and safe to handle, even in difficult site conditions