Weld Pass Marlborough- HaTelit® C

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

As part of a trial to find practical ways of extending the asset life of our roading network, Waka Kotahi NZTA looked to develop and study a 750m long test section of road within the Weld Pass, just south of Blenheim. This steep, winding road is a highly tracked freight route between Christchurch and Picton as well as being one of the main entry roads into the South Island for tourists arriving from Wellington.

HaTelit C was chosen as the flexible composite reinforcing geogrid to be tested. Now installed, Waka Kotahi will monitor the stress levels to see how that section of road compares to other sections that haven’t been resealed with HaTelit. Recent New Zealand and overseas studies show there will a marked difference. Depending on the results, this trial should motivate Waka Kotahi to introduce this installation process on future pavement projects as we look to move away from constantly repairing cracks and potholes by extending the life of New Zealand’s roads.

DESIGN

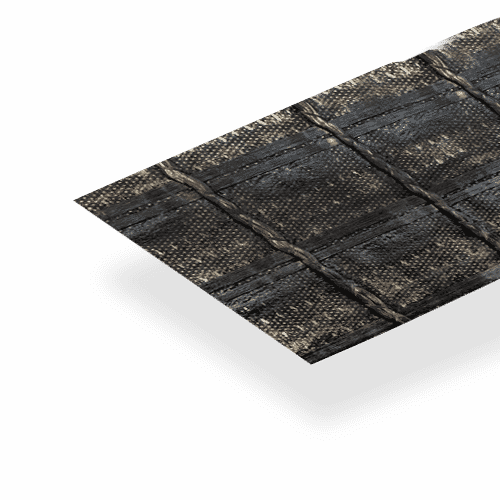

HaTelit C adopts and distributes the stress of crack tips rising from the lower pavement levels, effectively preventing reflective cracking from disturbing the upper bitumen layer. Used extensively on airport runways and motorways, HaTelit is designed to keep roads smooth under high stress loads.

Available as standard 4m wide rolls, the 6,000sqm of product was designed to be rolled out and sealed between the tack coat and the upper asphalt layer/wearing course. Due to the tight corners within Weld Pass, an optimum design of slightly overlapping lengths, cut at various angles was proposed before installation began, as the HaTelit product needs to cover the entire trafficable width of the pavement to prevent any reflective cracking from coming through.

INSTALLATION

With State Highway 1 being the main transport road between Christchurch and Blenheim, work was done at night-time to help manage traffic, with half an hour to let traffic through set between 12-12.30am. Further time pressure was put on the contractor due to only brief periods of fine weather at the time.

The most important part of HaTelit installation is the correct application rate of the tack coat prior to the placement of HaTelit. This ensures a strong bond between the HaTelit and the asphalt layer. The reinforcement grid works best when laid flat and free of wrinkles, so extreme wind could have been a hinderance, plus any rain would delay the asphalt placement.

A Cirtex Site Support representative was onsite during each night to make sure the cut lengths through the bends were placed according to the manufacturer’s installation guidelines. Overlapping sections were kept to a minimum, and these were secured using an extra bitumen spray, turning each of the joined layers into a singular stretch of material bonded to the layer below.

Although this test of how HaTelit C can help deal with the stress upon New Zealand’s roads, overseas installations show that it greatly extends the life of highly stressed pavements. This application of HaTelit will prove that the extra outlay during construction will vastly reduce ongoing road degradation, repair work, traffic interruption and vehicle damage in years to come.

The HaTelit provided the following benefits to the project:

- Prevents reflective cracking

- Gives a practical alternative to complete rehabilitation of existing roads

- Extends the life of highly stressed/fractured pavement

- Fast and simple to install