Winton Road Upgrade (SH6)- HaTelit® C

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

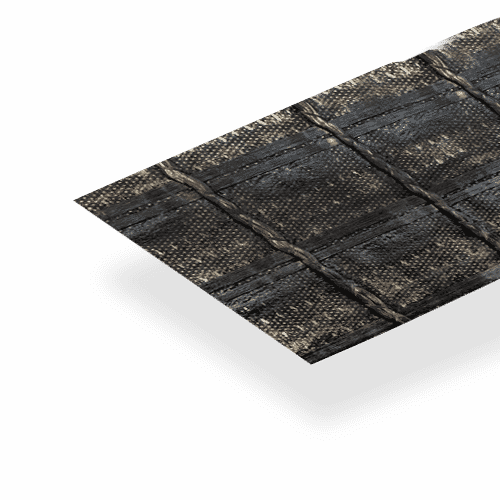

As the main road through Winton, State Highway 6 links Queenstown to Invercargill. Due to fatigue from weak support, the pavement surface suffered extensive cracking. Repairs were required, but as the road goes through the main centre of the town, any repair work would be a major disruption to local business and traffic flow. Split into four sections, a 270mm combined Deep Lift Asphalt Pavement was designed for the 1.5km stretch of road, but in one 300m section, initial test splits indicated that the underlying subgrade was so soft and so close to the surface that it would interface with the new 270mm deep lift layer.

In that situation, the road would normally require an almost 1m deep dig out. While viable as a construction method, this solution would entail a multi-week shutdown of the entire road. With the impact on local businesses far too disruptive, Downer sought an alternative asphalt solution. With Downer’s project manager for the site having used HaTelit C before, they were aware of various cases around the world where HaTelit C has greatly strengthened thin asphalt and increased the life of the pavement in situations where a deep dig was not economically viable.

DESIGN

The wall was required to bear the load of all heavy traffic accessing the winding coastal road. After initially submitting a The design of the 270mm combined Deep Lift Asphalt Pavement gave the new road an approximate 7-10 year design life. Owing to the nature of the soft subsoil conditions, however, it was uncertain how long the 300m proposed section would last. International research shows life expectancy of the HaTelit reinforced asphalt lasts 4-6 times longer, with Downer’s independent research predicting that the reinforced asphalt option would last approximately 9-12 years, while new un-reinforced asphalt would only last 3-4 years.

While there are hopes this section will be supported on its own, part of the design intent was to use this section as a bridge between the more solid sections of road, with HaTelit C helping to transfer load to areas that are more suitable. Downer’s engineers created an in-house proposal of milling off the pavement surface, laying an underlying 40mm asphalt layer of DG10, which would then be tacked, over which the HaTelit C reinforcing geogrid would be rolled out and covered with a 50mm overlay of AC14.

INSTALLATION

Due to rain events hampering progress, and because some traffic was still being diverted through the town during different stages of construction, the southbound section of the road was milled back and filled in two separate stages. Once the two strips were evenly filled with DG10 to meet the median of the main road, each strip was tack coated before the HaTelit C was rolled out. Being careful to make sure the two strips of HaTelit C met evenly along the length of the road, the Downer team made sure the reinforcement grid remained straight and wrinkle free. Where SH6 turned onto SH96, the HaTelit product was simply cut to meet the road’s curves. Once in place, the entire section of the southbound road was covered in 50mm of AC14 to create a continual, smooth surface.

This solution proved to be much more cost-effective and far less disruptive than a full dig out and installation of a completely new pavement. The road surface will be monitored. In the years to come, test cases such as this for resurfacing cracked and potholed roads using HaTelit C will change the face of long-term repairs for New Zealand’s road network.

The HaTelit C provided the following benefits to the project:

- HaTelit C prevents reflective cracking.

- It can be used to strengthen shallow asphalt layers.

- HaTelit C greatly extends the life of pavement repairs.