Vinyl Sheet Piles

Durable, easy to install, lightweight and economic alternative to the traditional solutions such as steel sheet piles, wood or concrete.

Ideal for civil and marine engineering projects, Vinyl sheet piling is a durable, eco-friendly, long-term alternative to traditional materials like steel, concrete, and wood, offering performance in harsh environments for flood protection, riverbank stabilisation, and retaining walls.

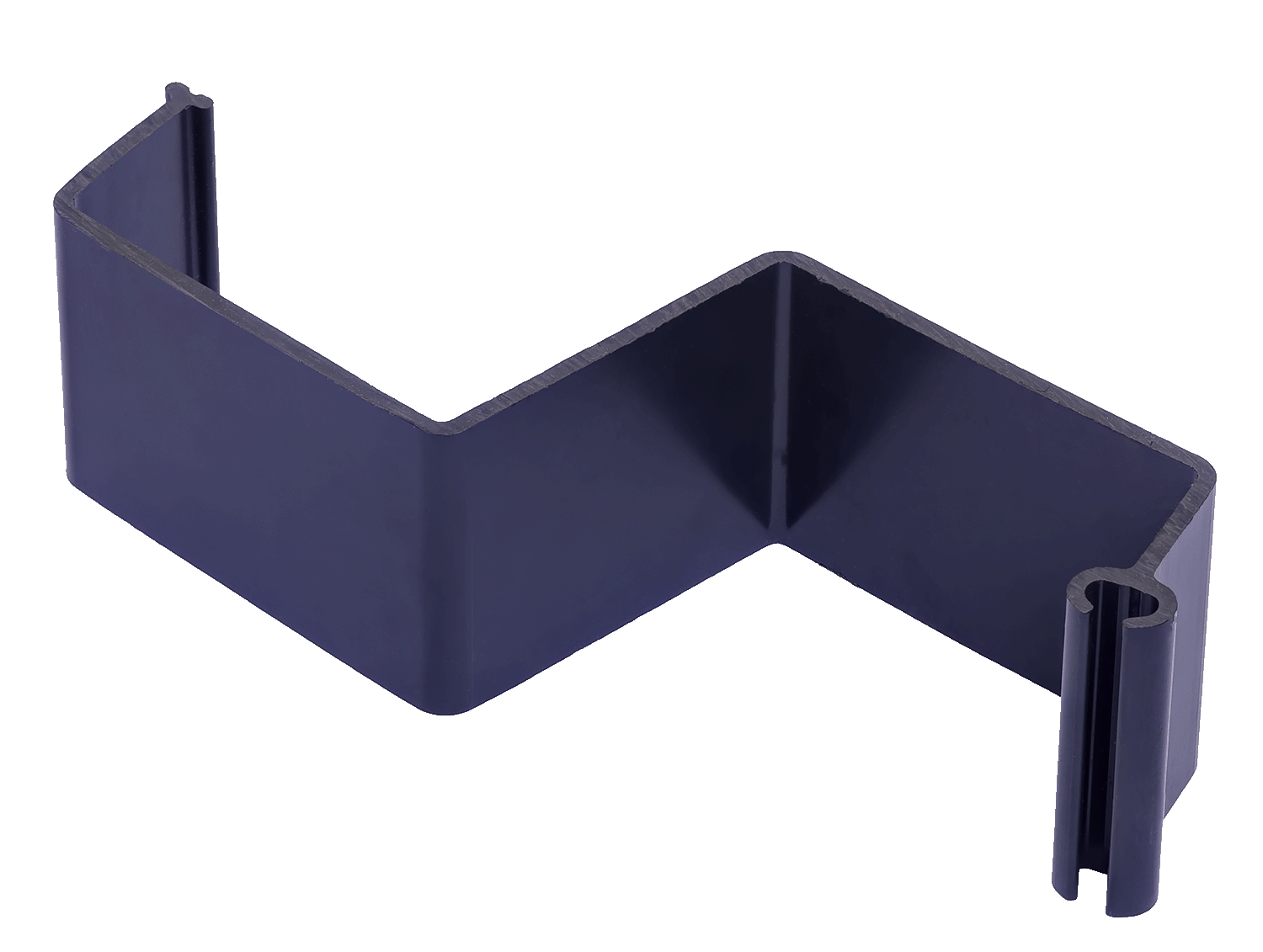

Made from robust polyvinyl chloride (PVC), vinyl sheet piles are highly resistant to corrosion, UV radiation, seawater, and mechanical damage. With a 50-year limited guarantee, they require no maintenance and maintain structural integrity even under pressure.

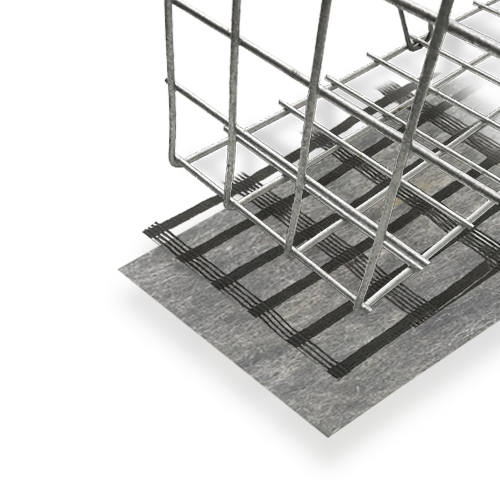

Vinyl sheet piling reduces costs due to its lightweight design, which simplifies transportation and installation. It can be installed quickly using standard tools, without the need for heavy machinery. Its flexibility makes it easy to adapt to natural curves in coastlines and riverbanks, reducing project time.

Applications for vinyl sheet piling include riverbank protection, flood walls, retaining walls, and cut-off walls in environmentally sensitive areas. Its combination of durability, cost savings, and environmental sustainability makes it a versatile solution for many construction projects.

Frequently Asked Questions

Vinyl sheet piling is lightweight, corrosion-resistant, and requires little to no maintenance. It offers long-lasting durability in harsh environments, while being more cost-effective to transport and install than steel or wood. It’s also an environmentally friendly option, as it’s made from recycled PVC.

Vinyl sheet piling is used in a variety of civil engineering projects, including riverbank stabilization, flood wall reinforcement, causeways, retaining walls, and cut-off walls. It is also ideal for areas with fluctuating water levels and for protecting sensitive ecological zones.

1. Riverbank Protection: Vinyl sheet piles can stabilize and protect riverbanks, ditches, or channels, adapting to natural terrain features.

2. Flood Wall Strengthening: These sheet piles are widely used to reinforce flood walls, adding durability and preventing water leakage.

3. Causeways and Water Structures: Vinyl piling provides robust protection against scouring in causeways, ensuring the longevity of the structure.

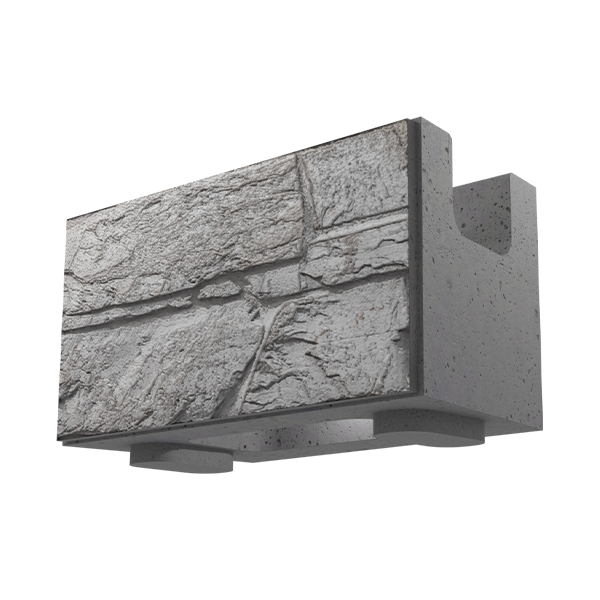

4. Retaining Walls: Used for slope and excavation protection, vinyl piles ensure both functionality and aesthetic appeal in shaping the land.

5. Variable Water Levels: With high tightness and adaptability, vinyl sheet piles protect banks subject to changing water levels.

6. Cut-off Walls: They reduce water infiltration and protect areas near environmentally sensitive zones, such as landfills and industrial sites.

Its lightweight design reduces transportation costs, while its ease of installation minimises labour and equipment requirements. Vinyl sheet piling can be installed quickly using standard tools, which significantly cuts down project timelines and overall costs.

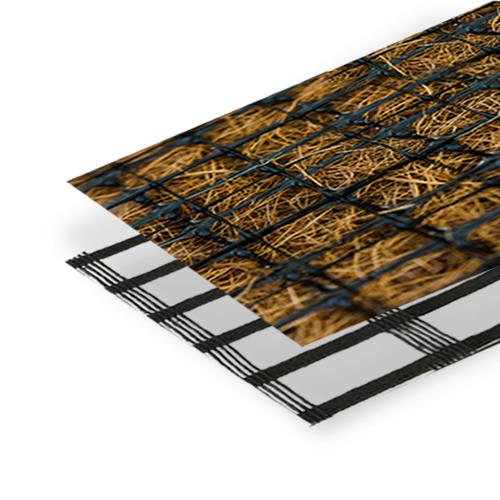

Vinyl sheet piles are made from recycled PVC and can be recycled again at the end of their lifespan. The manufacturing process uses a closed-cycle recycling method, making them a sustainable choice for environmentally conscious projects.

Yes, EcoLock vinyl sheet piles are available in a range of colours to match any aesthetic requirement, and their flexibility allows them to follow the natural curvature of riverbanks and coastlines, offering both functional and visual appeal.

Vinyl sheet piling is highly resistant to UV radiation, saltwater, and temperature fluctuations. It maintains its structural integrity even in harsh marine environments, making it a reliable choice for long-term use in challenging climates.

Benefits & Features

- Lightweight and durable

- Easy to install

- Made from robust polyvinyl chloride (PVC)

- Alternative to wood or concrete