State Highway 25 Underslip Repair – MagnumStone™ MSE System

Project Details

Contractor

Client

Engineer

Location

Cirtex Regional Contact

Project Information

In March 2023, heavy rain caused a section of State Highway 25 between Hikuai and Opoutere to fail. The underslip initially exposed half the outside lane, but as extreme weather conditions continued, the entire road soon collapsed. With SH25a already closed, severely limiting access to Coromandel Peninsula’s east coast, a temporary lane was cut into the hillside, giving one-way access to lightweight traffic only.

The slip site required a major retaining solution before the road could be rebuilt and allow normal traffic to resume, but additional scouring and erosion due to large amounts of water seeping through the hillside as well as water coming through an existing culvert were major obstacles to overcome.

DESIGN

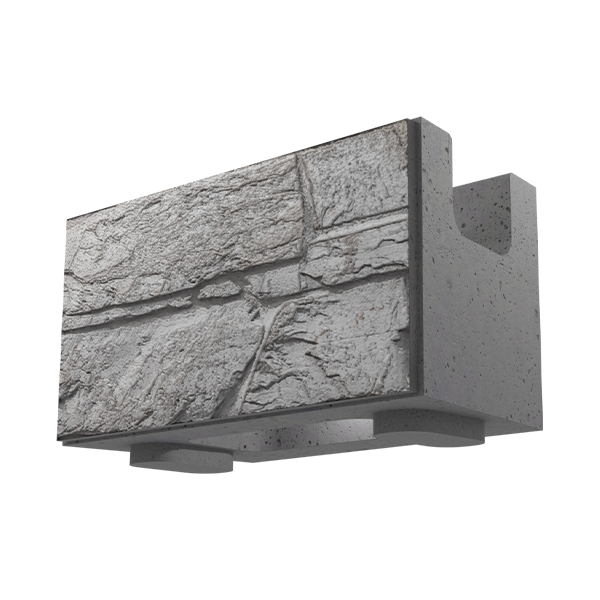

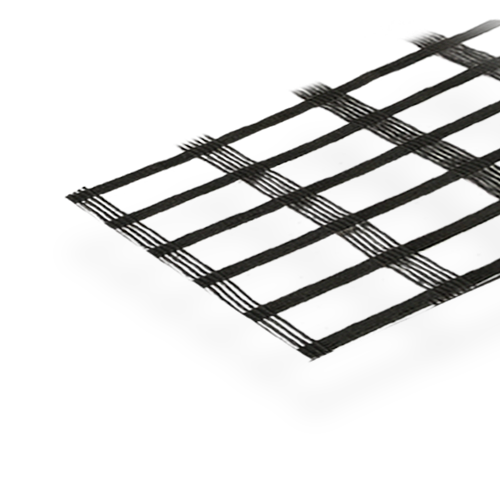

The wall was required to bear the load of all heavy traffic accessing the winding coastal road. A 45° wall would better match the surrounding landscape and provide better tie-in to the existing bank. A stepped wall was then designed, with each MagnumStone block set back 550mm onto a layer of compacted engineered fill. The bulk of the wall was designed as an MSE structure with StrataGrid reinforcement, but to allow the wall to meet the contours of the surrounding cliffs, the last 2-3 blocks at each end of the wall were designed as a gravity wall with extenders. This allowed flexibility of construction without changing the wall’s aesthetic.

To counter the large amount of water seeping through the site, a drainage blanket was designed underneath the wall, allowing the water to flow out without further affecting the wall. A larger culvert pipe was designed to exit near the top of the wall, giving easy access with a handrail for maintenance crews. To offer scour protection against the water flowing from that pipe, a concrete platform was also designed to fan out as it stepped down each level of the wall.

INSTALLATION

The initial challenge was to safely remove the slip debris. The extremely soft soil conditions meant the material had to be placed into a certified dump area with any runoff tested and treated. Cirtex was heavily involved by providing floc and bench testing for the dump site, while also limiting the silt material that ended up in river below. Once cleared, a concrete footing was placed to allow the first row of blocks to sit on a level site. All backfill material was brought in from a nearby quarry, Peninsula Aggregates, saving transport costs as well as minimising carbon emissions and damage to local roads. Higgins were able to place the blocks in the small site area using forklifts and cranes. As each row of blocks was laid, a compacted layer of GAP65 and the 300-400mm drainage blanket layer was placed, using a remote-control compactor to form each layer. With the next MagnumStone block resting on the inner edge of the block below, each level of aggregate needed to be perfectly levelled and supported. This was more challenging to construct but allowed for the creation of the 45° wall.

Once the wall was complete, the concrete scour protection was poured into the tops of each appropriate section of blocks, as well as at the base of the wall. A crash barrier was also reinstated, set slightly back from top layer of MagnumStone blocks, with a concrete channel and scruffy dome running through the temporary access track on the other side of the road. With the ground now reinforced, Higgins were able to create two lanes of traffic, opening both lanes when they were not working on rebuilding the road.

The MagnumStone MSE system provided the following benefits to the project:

- Able to change from MSE to gravity design without changing aesthetics

- Can be installed in tight site conditions

- Gives instant support for traffic once each layers is filled