- Menu

Civil Hub

Access a community driven forum, webinars on demand, technical drawings & advanced design software.

- ProductsFeatured ProductsGeotextilesGeogridsStormwaterReinforced Soil SystemsBlock Retaining SystemsGravity WallsGabionsSediment Retention PondsSite SuppliesSilt ControlDewatering & DrainageTurf MattingEarth AnchoringCulvert FlumesDrainage CompositesErosion Control MattingPermeable PavingImpermeable LinersPavement SurfaceGeocellsShear Lock®Concrete MattressesRock Bags

- Contact Us

Facebook

LinkedIn

Twitter

WhatsApp

It is typically the case across New Zealand that there is a requirement with any project of significant size to implement a chemical treatment management plan to assist with achieving compliant discharge standards in relation to sediment. Along with your Erosion and Sediment Control Plan which details the Environmental Controls for your site, you will also need a Chemical Treatment Management Plan for council approval.

A Chemical Treatment Management Plan details:

- The project location

- The nature of the works

- Bench testing from soil samples to ascertain chemical dose rates

- Methodology – i.e., rainfall activated dosing into an SRP and/or flow-base dosing

- Maintenance and reporting requirements

Bench Testing Process

At Cirtex, the bench testing is done at our GeoCert laboratory.

Representative samples are tested to ascertain the optimum dose rate to achieve compliance discharge and the results provided include Clarity, Turbidity (NTU) & Total Suspended Solids (TSS). PH levels are also recorded and detailed in the CTMP.

Representative samples are tested to ascertain the optimum dose rate to achieve compliance discharge and the results provided include Clarity, Turbidity (NTU) & Total Suspended Solids (TSS). PH levels are also recorded and detailed in the CTMP.

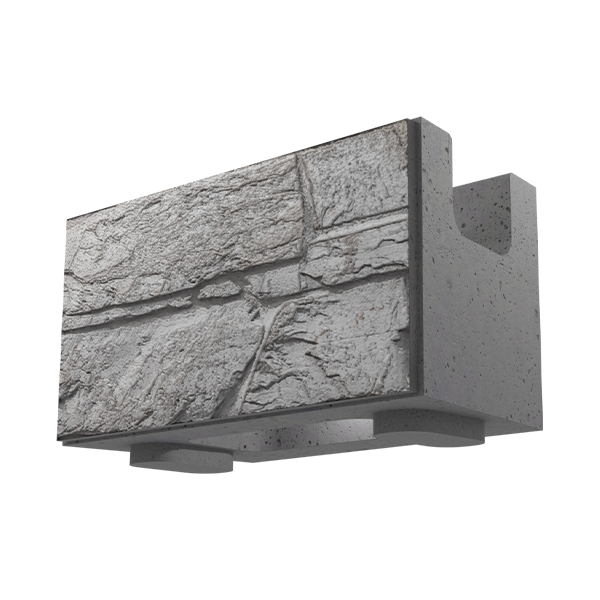

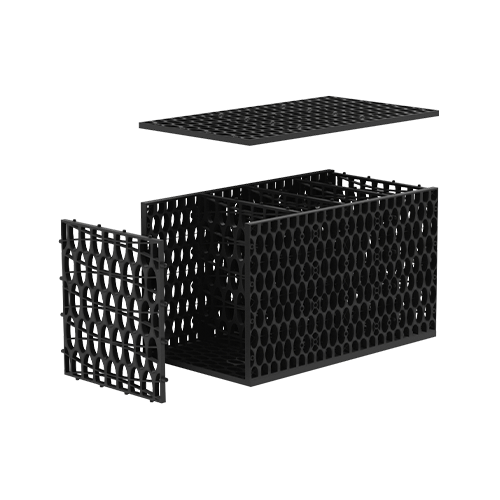

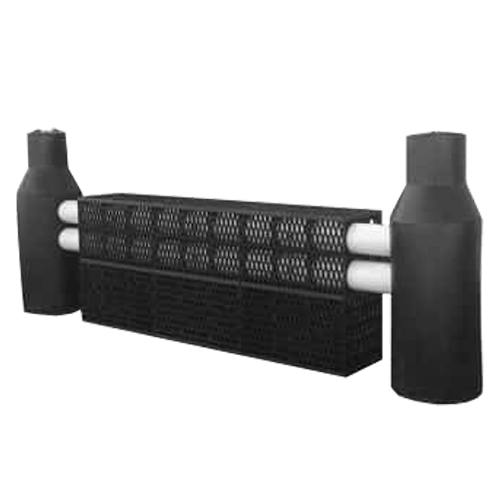

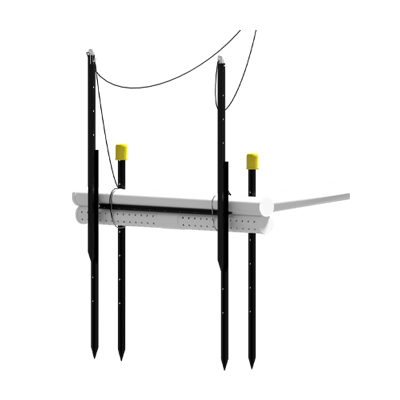

Floc Sheds/PortaFloc

Once Cirtex has completed your CTMP, we’ll also supply the materials you’ll need. As well as the traditional GD05 Floc Shed, Cirtex have developed the PortaFloc – a system that, while replicating TP90 GD05 floc shed principles, offers a whole range of operational and maintenance benefits.

Supplied as a standard or large size, the added benefits of the PortaFloc include:

- Quick set-up time on site

- Easily adjustable trays for different catchment parameters

- A screen to stop debris accumulation

- A streamlined header tank design

- A level indicator detailing current chemical and displacement levels

- An internal drain system for emptying the displacement tank

- 18mm filling connections for chemical replenishment

Chemical Supply

Cirtex supplies Polyaluminium Chloride in both 200L drums and IBC’s (Intermediate Bulk Containers). Wherever possible, we encourage the use of IBC’s. 200L drums are extremely difficult to recycle in New Zealand, whereas IBC’s have the following benefits:

- You can gravity feed your units (eradicates the need for pumps)

- The IBC itself has an afterlife, they make great water tanks

Please consider these when making the decision as to which one you need.

Please consider these when making the decision as to which one you need.

A Typical Dosing System Set-Up On Site

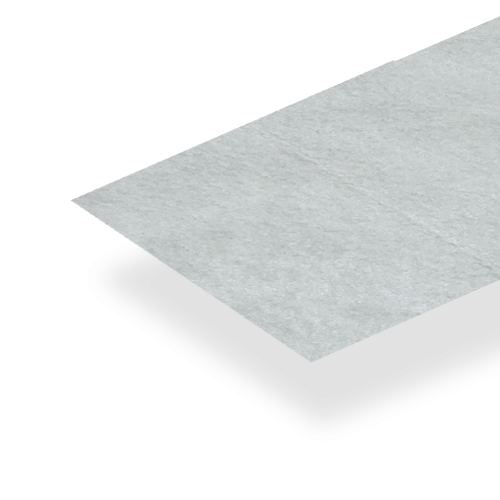

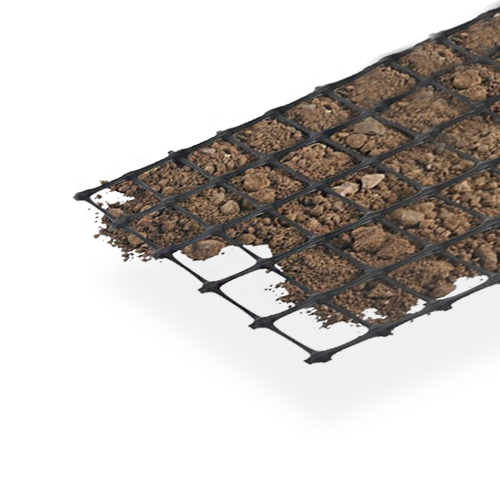

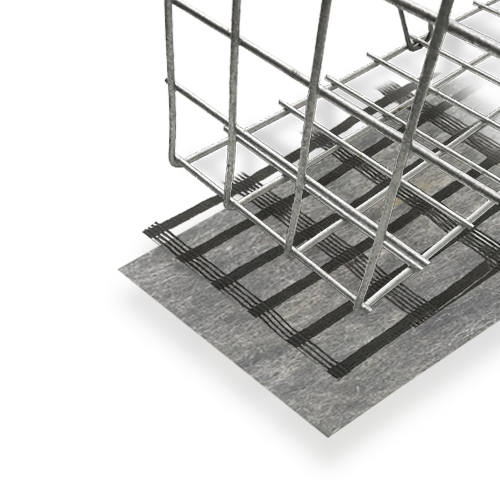

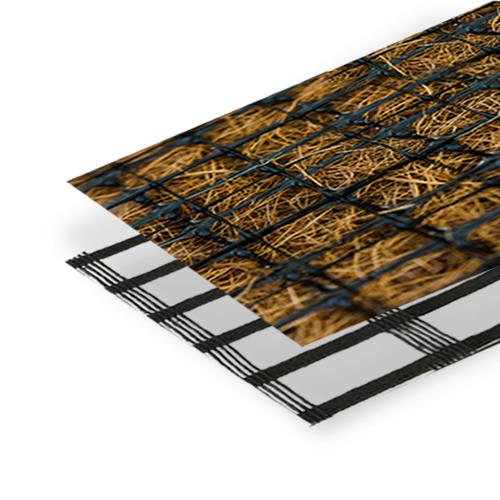

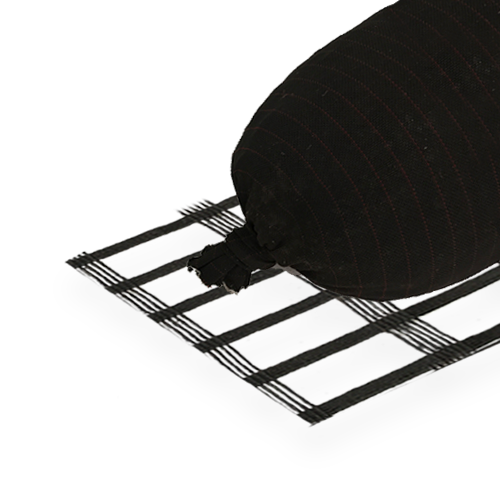

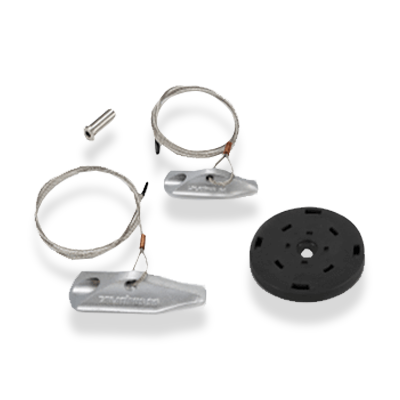

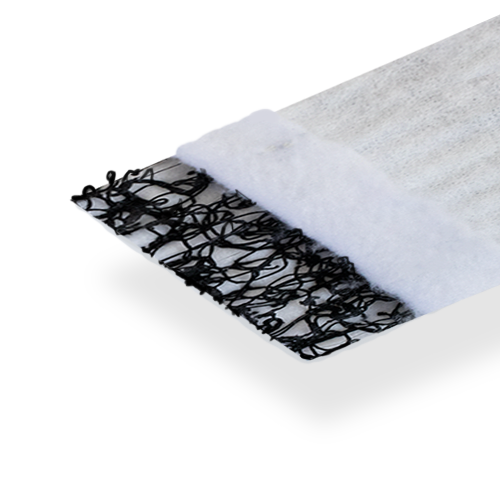

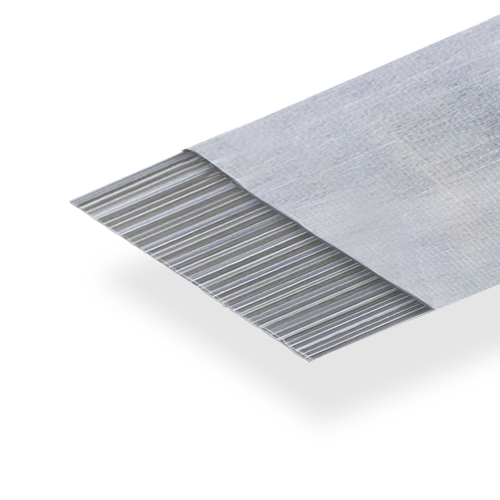

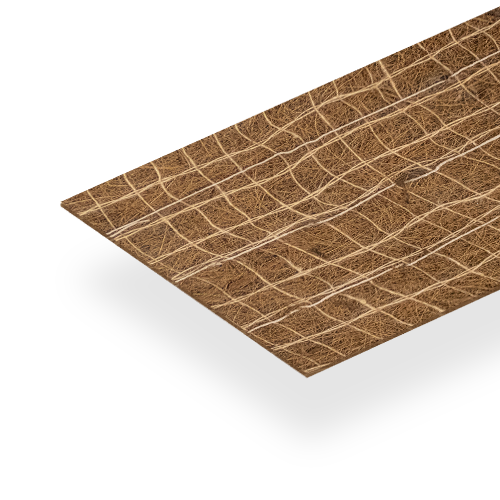

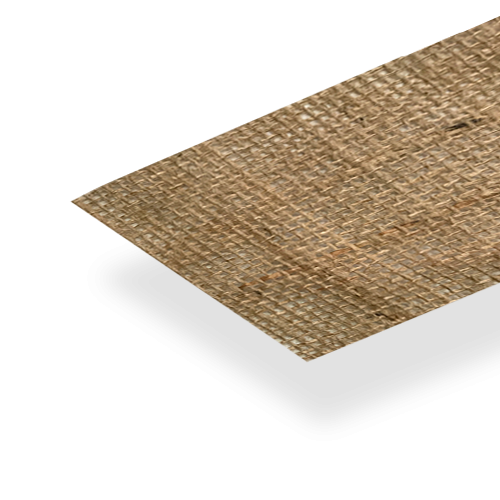

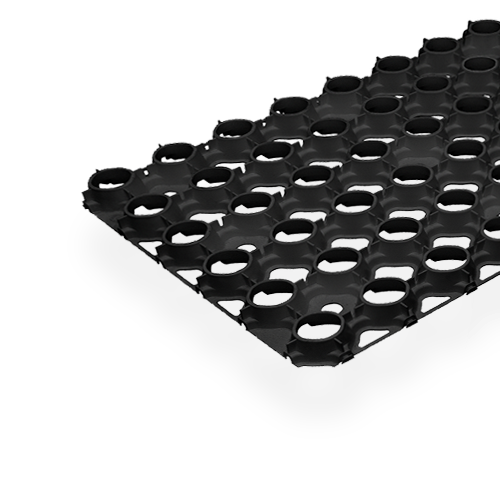

When locating a PortaFloc, we want to be dosing approximately 5m back up the entrance channel from the forebay. The chemical is gravity fed from the IBC. To achieve good mixture of flocculent prior to the entering the forebay, socks in the entrance channel concentrate water flow at the dose point, which sits about 6” above the ground. Too high, and the floc could blow away; too low, it can potentially get buried in the sediment. We also add geotextile beneath the socks to prevent scour and erosion from the concentrated water flow.

On-Site Testing

Our Field Test Kits will help you meet the 100mm clarity requirements. The Secchi grid and measurements up the side will give you all the readings you need to ascertain whether your discharge is compliant.  When recording pH, you can either use pH strips or a meter. Just be mindful that although pH meters will typically give you accuracy to 2 decimal places, they need to be calibrated regularly, potentially going out of range and losing accuracy if they aren’t. pH strips are 100% reliable as long as they’re kept dry and out of the weather.

When recording pH, you can either use pH strips or a meter. Just be mindful that although pH meters will typically give you accuracy to 2 decimal places, they need to be calibrated regularly, potentially going out of range and losing accuracy if they aren’t. pH strips are 100% reliable as long as they’re kept dry and out of the weather.

In-Field Training and Support

As part of putting together your Chemical Treatment Management Plan, we will also:

- Make a time with you to meet on site

- Look at any existing dosing systems on site and make recommendations accordingly

- Do set up and installation training

- Make sure everyone on site has a clear understanding of their responsibilities

- Show you how to do your clarity and pH testing

- Offer further remote assistance for any changes occurring for the duration of your project

Civil Dosing Hub

On the Civil Hub, you will find a Dosing Calculator that allows you to generate and understand new catchment and dosing rates as your project adapts. Once you’ve detailed the project, typically the details as per your CTMP, you can amend catchment areas and dose rates, which is useful if you’re closing or opening areas, or if your soil types have changed. Select the system you’re using (a shed, floc box or PortaFloc). The Civil Hub Dosing Calculator will generate the new catchments sizes and dosing rates that can be put back into your CTMP as an amendment. When your monitoring officer comes on site, you’ve got full understanding and justification for your current sizing on your system.

Cirtex Video Resources

Our Cirtex website has informative video resources available. Among a range of case studies, you’ll find the following films:

- Floc Shed – Overview and Workflow.

- PortaFloc Dosing System – Overview and Operation.

- Decant System – Overview and Operation.

Cirtex are also very supportive of industry initiatives. As an example, at a recent Waikato E&SC Field Days, we were on-site, showcasing how a successful flocculent dosing system works, taking the murky water in the forebay right through the pond system to clean water being decanted out at the other end.

Cirtex are also very supportive of industry initiatives. As an example, at a recent Waikato E&SC Field Days, we were on-site, showcasing how a successful flocculent dosing system works, taking the murky water in the forebay right through the pond system to clean water being decanted out at the other end.

Give the team at Cirtex a call to discuss how we can assist you in developing a Chemical Treatment Management Plan that suits your project and your environment, make use of the bench testing at our GeoCert laboratory, or to enquire about how we can supply the materials you need for your project.